Description

MultiGrup system comprisses: multilayer pipe, brass fittings, connecting tools to attach the pipe to the fitting and mounting accessories to work.

Scope

MultiGrup System is designed to use in plumbing installations for hot and cold water, heating radiators and floor heating.

In all cases the application must be made at the temperatures and pressures described for each type of application in the standard UNE-EN-150-21003.

System Components

Pipes

MultiGrup (PE-RT / AL / PE-RT) pipes are made up of five different layers:

· Inner layer of temperature-resistant polyethylene (PE-RT)

· Adhesive layer of high temperature

· Intermediate layer of aluminum butt welding

· Adhesive layer of high temperature

· External layer of temperature-resistant polyethylene (PE-RT)

Product certificate: AENOR 001/007142 and CSTBat 4440-278-1950-V2.

The main feature of the multilayer tube is the presence of the aluminium intermediate layer which gives the tube a remarkable resistance to pressure,

as well as conferring opacity to oxygen diffusion.

Some of the technical characteristics of the pipeline are:

Feature Value

Maximum Service Temperature 95ºC

Maximum Punctual Temperature 110ºC

Absolute roughness 0,007 mm

Linear Expansion Coefficient 0,025 mm/m

O2 permeability < 0,1 g/m3d

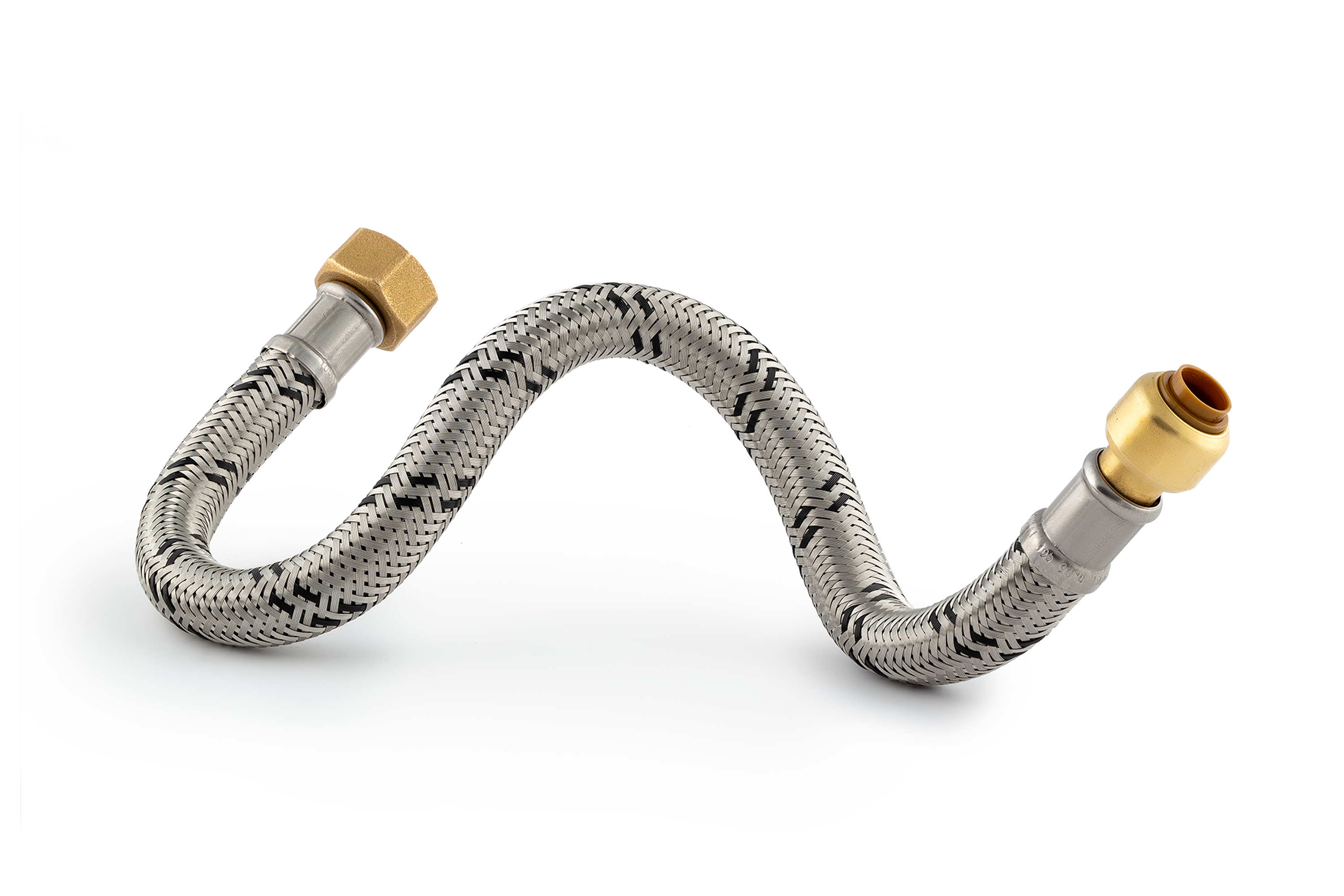

Accessories

Accessories are made of brass and CW614N standard CW617N, with latest technology of tinned coat.This coating gives excellent organoleptic and

aesthetic qualities to the piece. The dimensions follow the specifications of the standard EN1254 / 3 and are designed to ensure the perfect grip and

seal of tube.

The pressed Sleeve is made of stainless steel AISI 304, which ensures perfect corrosion resistance.

Accessories have their own O-rings in EPDM with high resistance to high temperatures.