Twist O2B - Twist O2B ACB

Twist O2B - Twist O2B ACB

Description

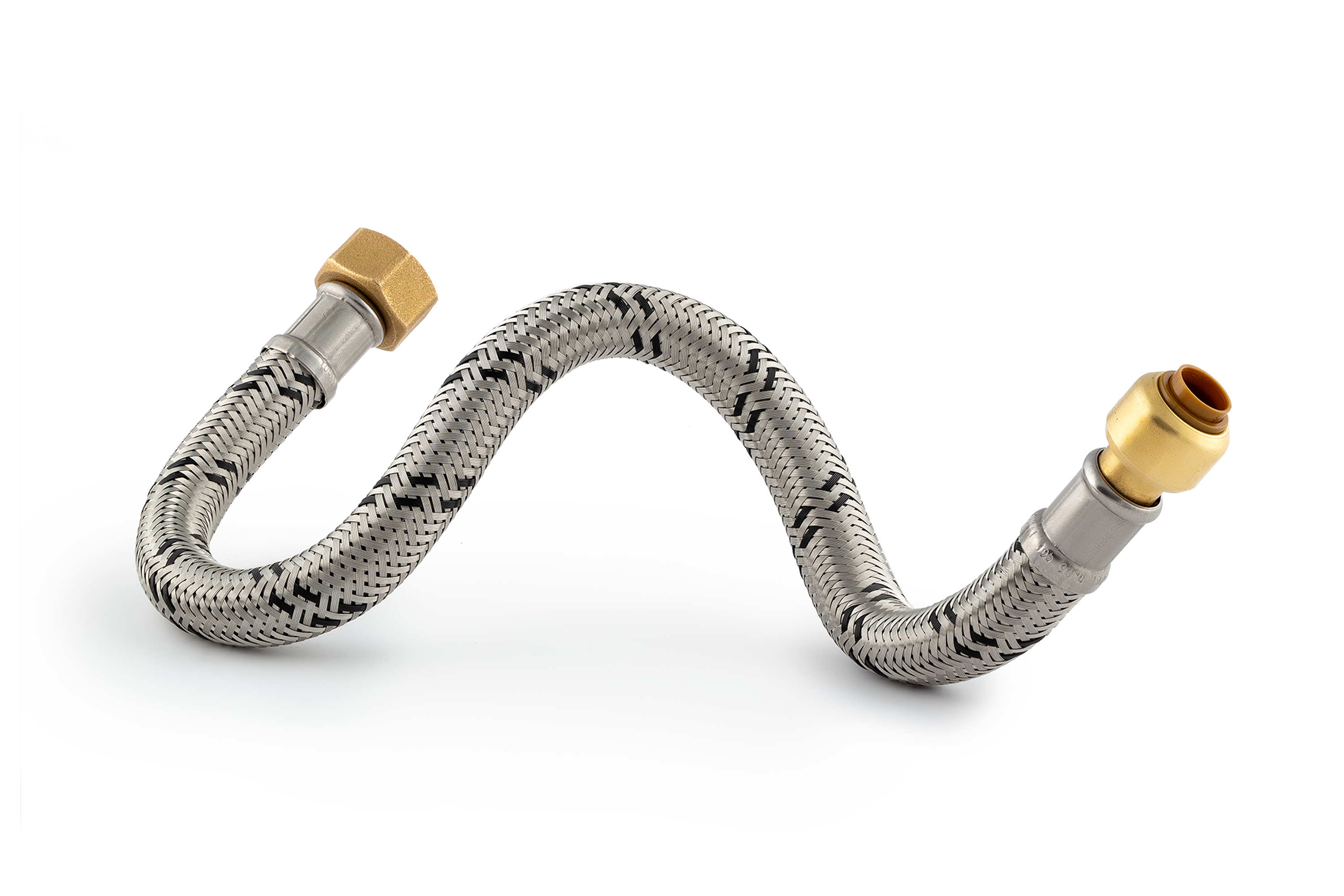

The ideal solution for hydronic heating and cooling systems.

Flexible connectors with oxygen barrier are the ideal solution for the installation of hydronic heating and cooling systems. Excessive oxygen entering the system can lead to premature failure of ferrous metal components due to corrosion and cause wide spread system failures. The oxygen barrier reduces drastically the amount of oxygen in the system, helping to prevent rust or corrosion in metal parts and avoiding the formation of biofilm and mud in the piping

system due to water deterioration. This is key to keep the efficiency and rated energy saving of the heating and cooling systems, and helps to minimize the related maintenance operations.

Oxygen diffusion resistance according to DIN 4726 Oxygen diffusion into the pipe system increases the potential for corrosion in metal components.

The oxygen barrier layer prevents oxygen to diffuse into fluids. It is integrated in the pipe by an extrusion process to ensure that oxygen cannot penetrate through the pipe wall over the time.

The introduction of oxygen into the system could contribute to the hot and cold pressurized water pipework deterioration. DIN 4726 has been specifically developed to evaluate the diffusion of oxygen into refrigeration and heating systems.

(*) A pipe with no oxygen diffusion barrier has an oxygen permeability of more than 2g/m3.

INSTALLATION BENEFITS

1. Provides huge cost savings to builders as installation time is reduced up to 40%.

2. Extremely light. Easy to handle on site.

3. Permanent leak-proof union.

4. The assembly by means of simple push fit couplings provides excellent TOOL-FREE connectivity in confined spaces.

5. No risk of fire from blow torch nor solder splatter.

6. 100& oxygen diffusion proof. Tested to DIN4726. Eliminates the risk of corrosion in metal components.

7. Excellent bending radius. Does not collapse. Guaranteed flow rate.