Description

K65 - Sustainable and efficient

Sustainable and efficient – two keywords that have had a decisive impact on our time and have gained in relevance in recent years, especially in refrigeration. Increased environmental awareness in society and industry has therefore led to a kind of renaissance of natural refrigerants, especially CO2. Wieland supports this turnaround with a tube system that meets the high requirements of CO2 as a refrigerant.

Wieland K65 tubes have been designed for CO2 applications in the commercial field, especially that of supermarket refrigeration systems. Wieland K65 alloy provides the mechanical strength high enough to withstand the high operating pressures of CO2. At the same time, K65 tubes have outstanding processing properties, similar to those of standard copper (Cu-DHP/C12200).

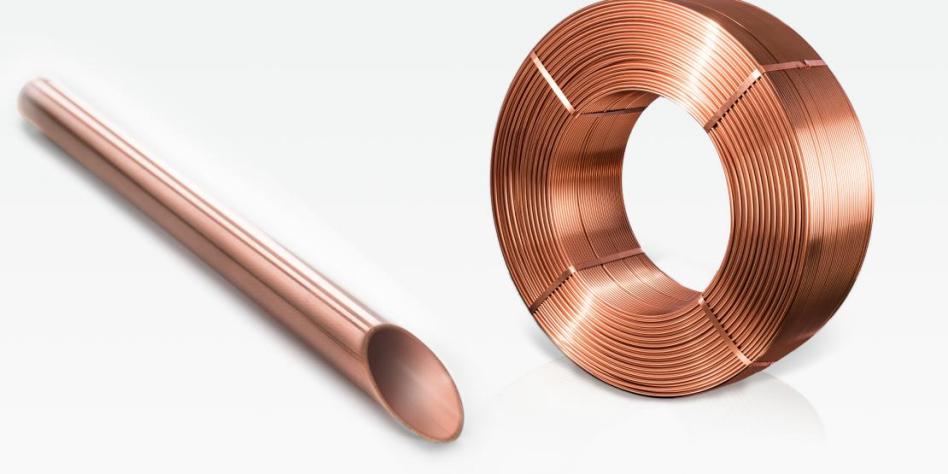

All Wieland K65 tubes are available in the soft condition (R300/O61) to ensure excellent bending / flaring and collaring properties.

Wieland K65 tubes are offered from stock in two pressure ranges, 80 bar and 120 bar, and in dimensions ranging from 3/8” up to 2-1/8”.

Moreover, K65 tubes are also available in individual dimensions and different delivery forms.

For industrial processing, in particular CO2 heat exchanger (evaporator / gas cooler) manufacturing, level wound coils (LWC) are offered.

More K65 products in other categories

- K65 in Refrigeration and medical gas tubes

- K65 Industrial tubes innerrooved

Your benefits

- Pressure resistance tailormade to your needs

- Cost reduction through weight reduction

- Proven processing technology: brazing instead of welding!

- Excellent heat transfer

- Design according to EN 14276 - TUEV or UL certification on demand

Typical applications

- Components of R744 refrigeration systems

- Fin coil heat exchangers for higher operation pressures (e.g. R744 evaporators or gas coolers )

- Shell and tube heat exchangers for higher operation pressures (e.g. R744 evaporators or gas coolers)

Technical properties

- Material: K65

- Conditions: soft R300/O61 and hard R420/H80

- Delivery form: Level wound coils or straight lengths

- Coil weights: 100 kg, 150 kg, 300 kg

- Available dimensions: 5 - 28 mm for LWC; 5 - 110 mm for straight lengths

- Usual standards: EN 12735-1 / EN 14276 / ASTM B 1017