Sustainable materials for sanitary and HVAC equipment

In the past, the choice of raw materials for sanitary and HVAC equipment was based primarily on technical properties, the costs and compliance with the relevant standards and regulations. Nowadays, there is a growing focus on sustainability, which is taken into account, for example, by using appropriate materials to ensure a long service life and recyclability throughout the whole life cycle.

Sourcing raw materials for sanitary and HVAC products: resilience in the supply chain

Efficient sourcing is essential for sanitary and HVAC manufacturers to ensure production continuity and product quality.

- Local sourcing of raw materials can make sanitary and HVAC manufacturers less dependent on international markets and shorten delivery times, as well as reduce transport costs and CO2 emissions. A comprehensive life-cycle analysis is important to weigh the environmental friendliness of local materials in comparison to imported raw materials.

- A diversified supplier base increases supply-chain resilience in the face of market turbulence or bottlenecks. At the same time, establishing strategic partnerships with key suppliers is crucial. Although a complex supply chain can help spread risk, it can also make traceability and quality assurance more difficult.

- Modern technologies such as IoT, blockchain and advanced analytics ensure improved traceability of sanitary and HVAC materials and greater planning certainty. However, challenges such as costs and integration into existing systems, not to mention data protection and cybersecurity, should not be underestimated.

A well-thought-out supply chain stabilises the sanitary and HVAC business and supports the integration of sustainable and innovative raw materials into production processes.

Sustainable sanitary and HVAC raw materials: circularity is trending

There are many ways to achieve sustainable materials for the sanitary and HVAC sector, especially renewable raw-material sources, recycling and biomaterials.

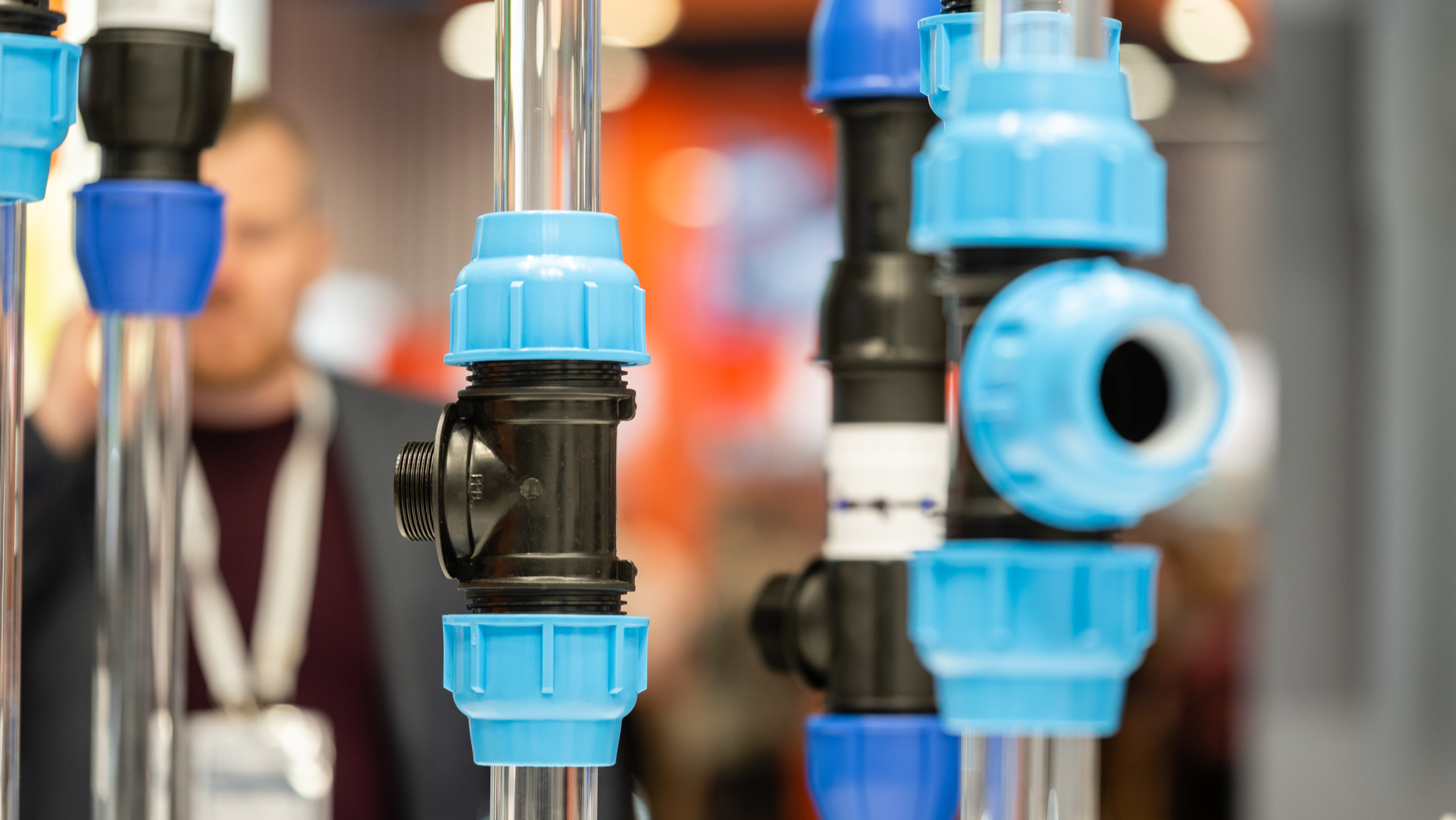

- Recycled materials such as PVC and polyethylene (PE) are often used in waste-water pipes, drainage systems and, sometimes, in drinking-water pipes, too. While these materials make an important contribution to the circular economy, sanitary and HVAC sector experts must carefully evaluate their quality and durability compared to new materials, especially in hygiene-critical applications such as drinking-water pipes.

- Bio-plastics and natural rubber from ethical sources are used, for example, in thermostats, control valves and seals. However, availability and processability are issues that have yet to be fully and universally resolved.

- Aerogels, which contain recycled silicates, have excellent thermal-insulation properties. However, they are not yet in widespread use due to their high costs and the challenges involved in processing them. Furthermore, their performance can suffer in humid conditions, and this needs to be considered during the planning phase.

- Although regenerative materials such as hemp, sheep's wool and cellulose are finding their way into the thermal insulation of heating and piping systems, they are still limited in terms of the areas in which they can be used, and hybrid systems are often required to achieve the desired technical performance.

- Glazes made of recycled glass are increasingly being used to surface-finish ceramic sanitaryware.

- In the case of fittings, especially those intended for drinking-water systems, using brass with a lower lead content helps reduce pollutant levels.

These developments illustrate the importance of focusing not only on the main raw materials, but also on the minutiae of material composition and processing. Besides the choice of materials, reducing waste and energy loss is an important trend when it comes to sustainable sanitary and HVAC products. Industry standards play a crucial role here. Standards such as DIN EN 1057 for copper tubes or DIN EN 10088 for stainless steel help ensure material quality. Moreover, they increasingly take account of environmental aspects, which are essential for sustainable choice of materials.

The future of sanitary and HVAC raw materials depends on a continuous process of evolution. ‘Green’ manufacturing processes that reduce CO2 emissions during the production of metals such as steel and copper are growing in importance. Work is also underway to develop fully biodegradable raw materials for temporary installations or secondary applications. ISH 2025 is the ideal venue to discover the latest trends and innovations in the world of raw materials for sanitary and HVAC products.