Description

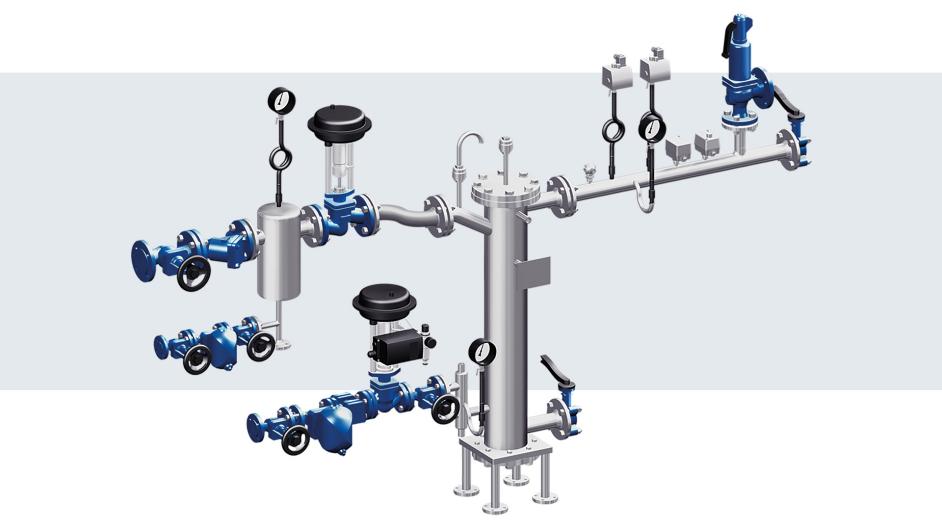

ENCOsys®

Heat exchanger systems

With energy-efficient steam pressure control for heating systems or fast steam-side control for process applications

ARI-ENCOsys® systems are built on a stainless steel frame. The safety devices which DIN EN 12828 requires (or acc. to country regulations) to be installed in heat generating systems are selected and integrated according to the system’s heat capacity. The use of smart control technology ensures that the upstream flow temperature is maintained at precisely the set value. When a safety component trips, the primary energy is reliably shut off and the system is transferred to an operationally safe condition. The heat capacity, materials to be used, design of control valves, etc. are individually adjusted to the local condition according to the customers application.

If necessary, the systems are equipped with actuators in acc. with DIN EN 14597 (temperature control devices and temperature limiters for heat generating systems).

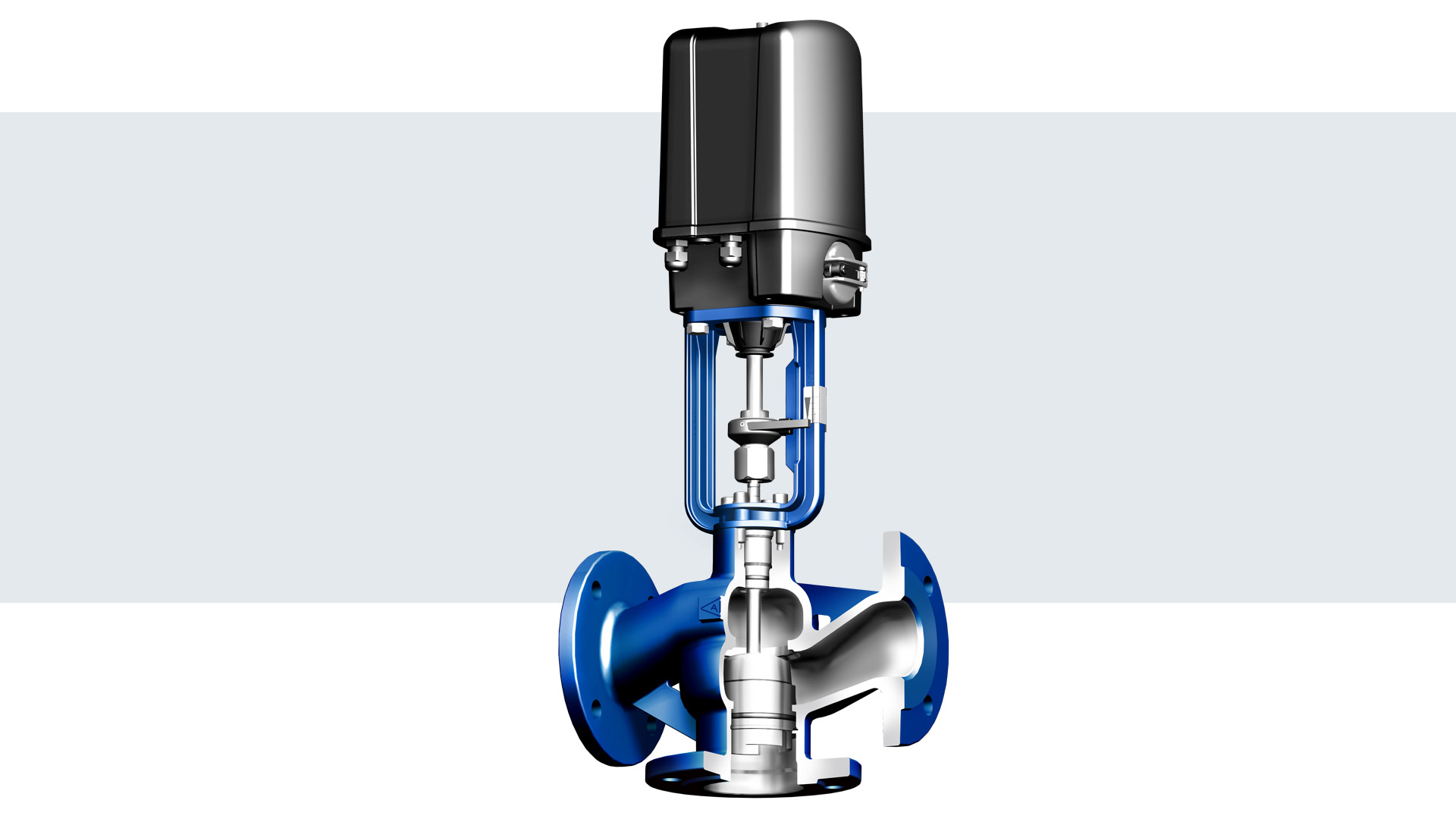

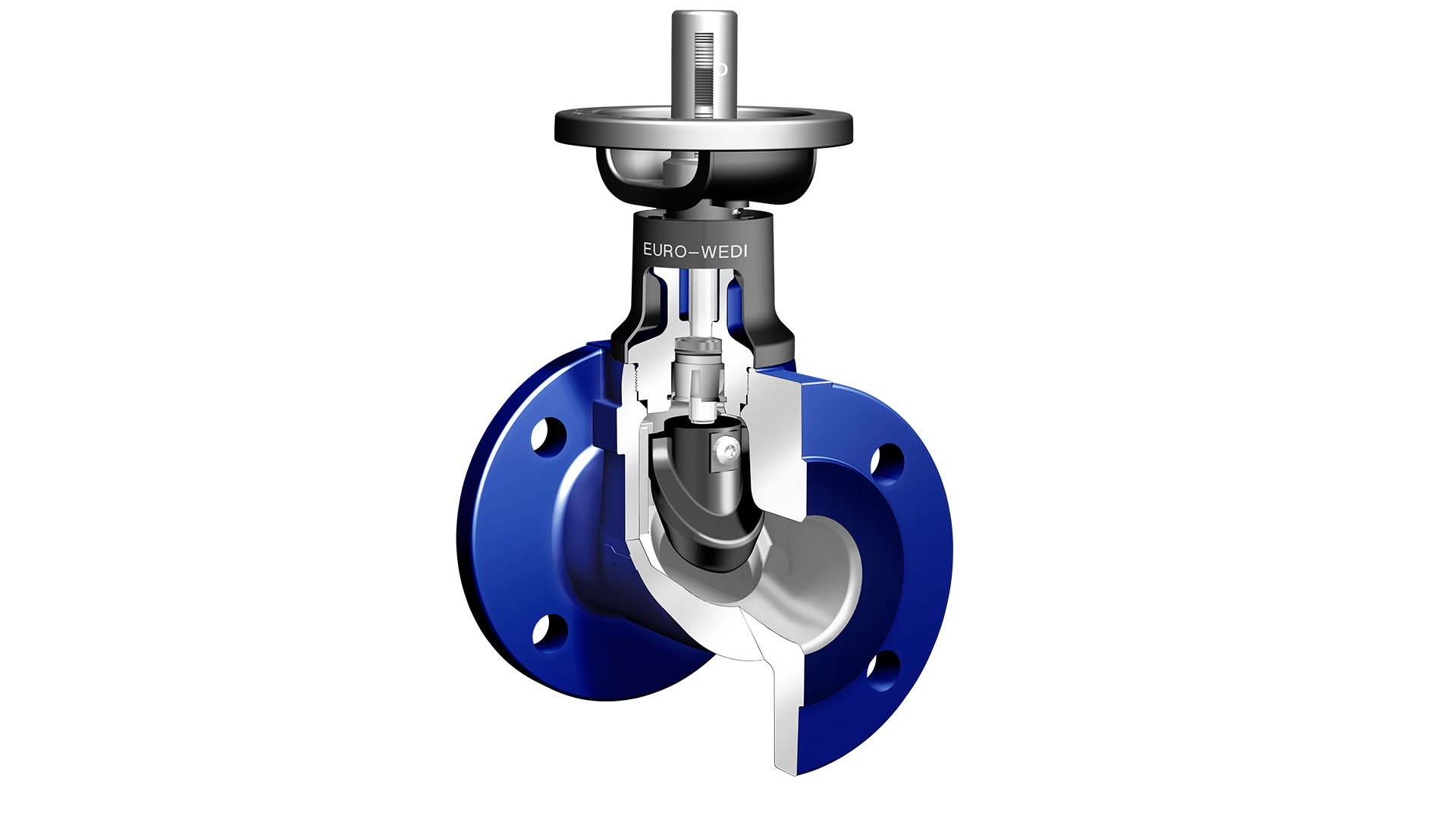

Energy-efficient condensate accumulation control for heating systems

The heat transfer process is achieved using a vertical, high-performance shell-and-tube heat exchanger. It is controlled by a control valve on the primary side (condensate outlet from the heat exchanger). The control valve regulates the level of condensate in the vertical heat exchanger. The condensate level in the heat exchanger rises or falls depending on the system load case. This ensures a precise upstream temperature on the secondary side.

- Energy-efficient solution

- CO2 reduction through up to 15% less steam consumption

- No flash steam– no water hammer!

- Compact design

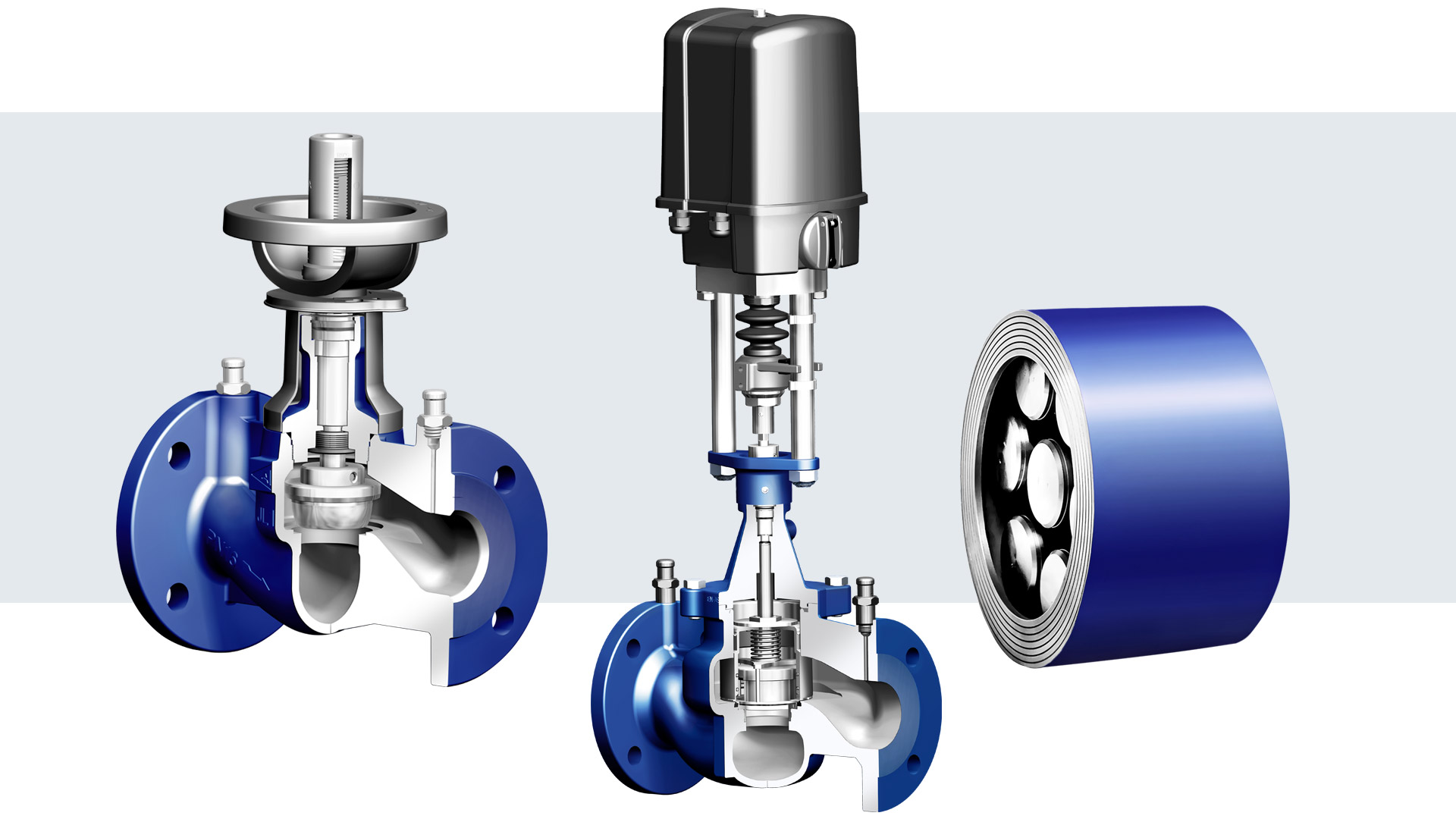

Fast steam-side power control for process applications and heating systems

The heat transfer process is realised by a horizontal highperformance shell-and-tube heat exchanger. It is regulated by a control valve on the primary side (steam inlet to the heat exchanger). This system is ideal for applications with low hysteresis and discontinuous processes with rapid load changes.

- Fast reaction to load changes (discontinuous processes)

- Efficient control for processes

- Robust and operationally reliable design thanks to shelland-tube heat exchanger