You can find the Interactive Hall Plan 2025 here.

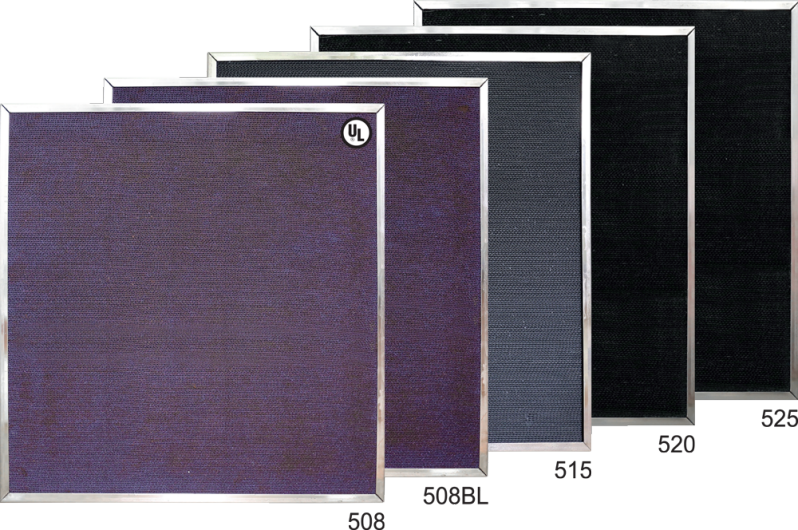

Gas Phase Honeycomb Filter

Gas Phase Honeycomb Filter

Description

Dry-Air Honeycomb Chemical filter, DRISORB series, is an 'in-situ' synthesized/deposited (insoluble metal silicate and activated carbon) macroporous desiccant honeycomb matrix, impregnated with a choice of oxidizing agents and alkaline solutions. It has high efficiency and reliability. The filter is specially designed for higher airflow, therefore, requires a lower surface area and has a lower pressure drop.

Unique Features:

- Bulk density >320.3 Kg/Cu.mtr. (> 20 Lbs./Cu.Ft.)

- Honeycomb monolith media available in 1'' to 12''depth in standard and custom filter sizes

- Tested in accordance with ASHRAE 145.2 P and ISO 111555-2

- Higher airflow range from 2.0 -3.0 m/s (400-600 FPM)

- 100% efficiency

- Tested by most respectable RTI lab of the USA

- Longer life (higher MTBR)

- Available in a combination with various impregnates

- Very low-pressure drop

- Backed by DRI's cutting-edge state-of-art R&D and testing facilities

- UL certified media

Advantages of DRISORB™ Filters

- Optimum choice for places with space constraints

- Impregnation % higher due to its design

- Easy to replace and maintain

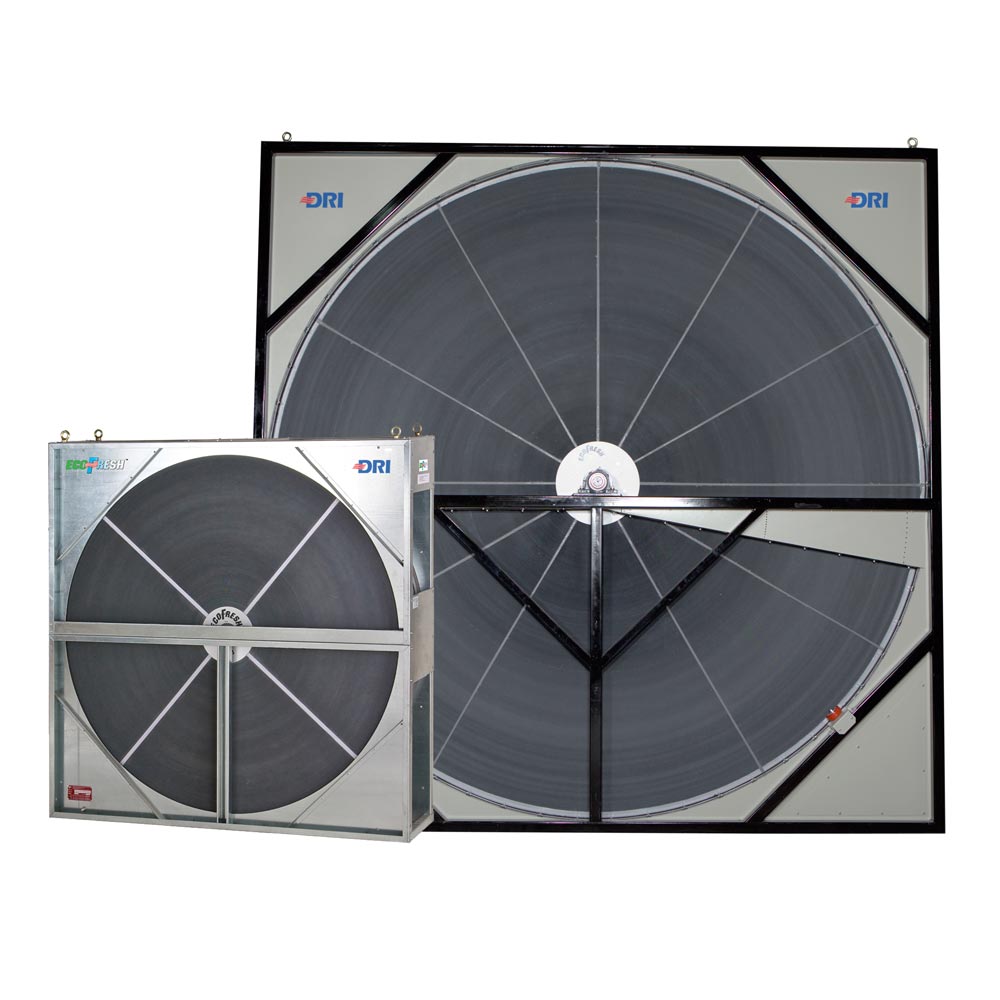

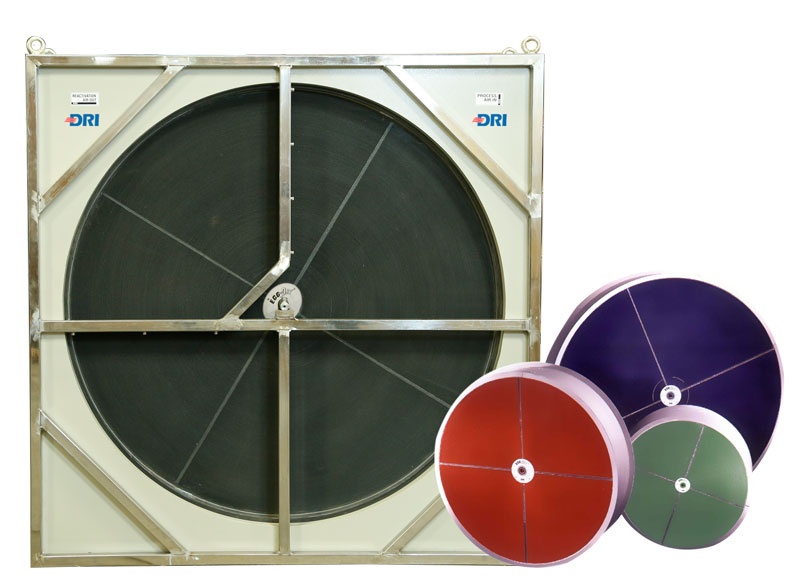

DRI V Bank Cassettes & Cartridge Filters:

DRI offers various types of V bank & round Cartridge filters for different industrial & commercial applications, with a choice of pocket depths & low surface velocities.

The V Bank Cassettes & cartridges are made of made stainless steel.