Description

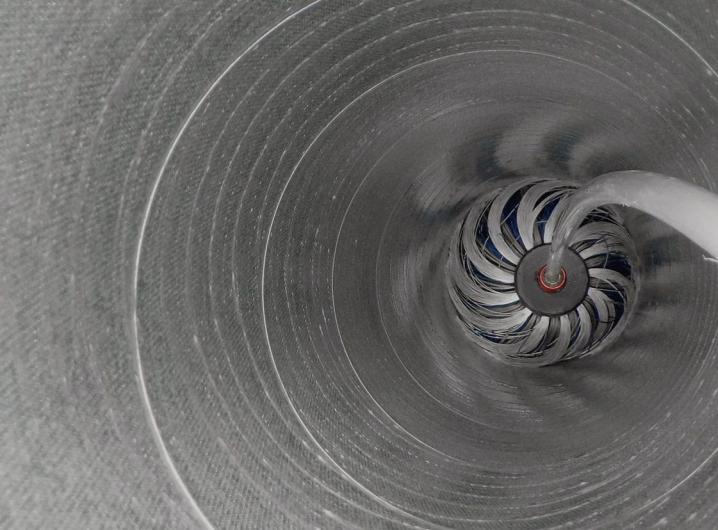

Cleaning & Disinfection of Ventilation Systems

We clean and disinfect according to VDI 6022, DIN EN 15780 2 – with a success guarantee!

Hygienic cleaning performed by Igienair in compliance with VDI 6022, DIN EN 15780 ensures the functionality and hygienically flawless operation of your ventilation systems (RLT systems) and cooling towers, meeting the latest technical standards.

Igienair is a certified specialist for the hygienic cleaning and disinfection (state-certified disinfectors) of mechanical ventilation systems, RLT systems, and evaporative cooling systems. Strictly adhering to VDI 6022, DIN EN 15780 guidelines, we ensure clean, fresh, safe, and standards-compliant ventilation systems in your facilities. Our highly qualified staff is happy to provide these services, guaranteeing clean indoor air and preventing health issues such as Sick Building Syndrome (SBS) or Legionellosis.

What is Sick Building Syndrome?

SBS affects individuals who spend extended periods in buildings where the indoor climate provides a conducive environment for germs and pests. As a result, HVAC systems in such buildings require frequent inspections and disinfection. We can explain how to prevent unwanted downtime, illnesses, and reduced productivity during an on-site consultation. Upon request, we will create a hygiene plan to maintain air quality.

Limescale deposits, contamination, or biofilm in cooling towers or humidification systems with recirculated water can lead to the growth of Legionella and Pseudomonas bacteria. This is why regular cleaning and disinfection according to VDI 6022 is essential.

Other Essential Cleaning Services

- Evaporators, condensers, air heaters, cooling shelves, and textile ducts: Thorough cleaning prevents germ or pest infestations.

- Smoke extraction and kitchen exhaust systems: Fire protection cleaning according to VDI 2052 ensures fire safety.

- Production and extraction systems: Cleaning components like ducts, outlets, valves, fire dampers, and all other ventilation system elements improves performance and operational efficiency.

Our Services in Compliance with VDI 6022

Your Benefits:

- Standards-compliant and documented cleaning according to GMP

- Tailored and customized solutions

- Professional and expert disinfection

- Court-admissible documentation, including before-and-after photos

- Microbiological sampling with analysis by accredited laboratories

- Free follow-up treatment / warranty services

- Rapid system availability and minimal downtime, thanks to an optimized number of technicians

Let us provide you with clean air, better efficiency, and peace of mind for your systems!