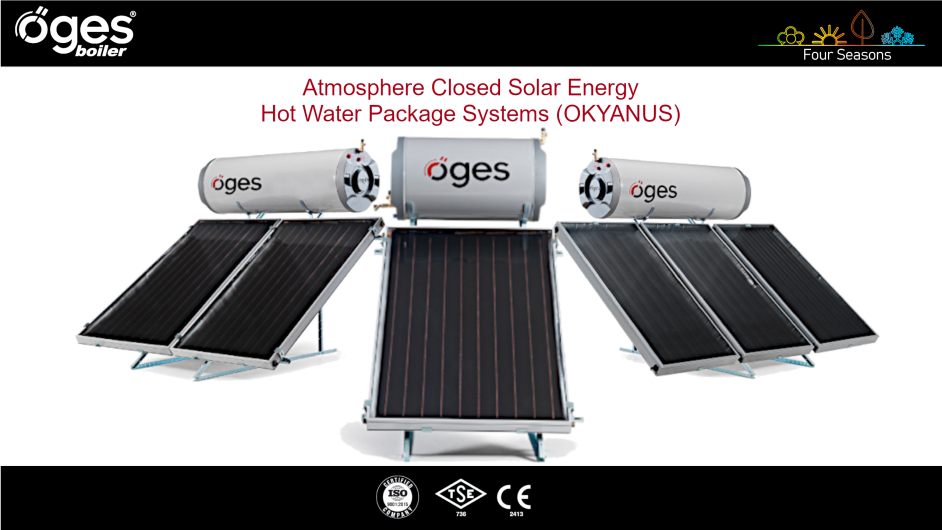

ATMOSPHERE CLOSED SOLAR ENERGY HOT WATER PACKAGE SYSTEMS (OKYANUS)

ATMOSPHERE CLOSED SOLAR ENERGY HOT WATER PACKAGE SYSTEMS (OKYANUS)

Description

ADVANTAGES

OKYANUS systems are pressure systems that work directly with city network without cold water supply or float addition as an open circuit without anti-freeze or a closed circuit with anti-freeze. The inner surface is coated with titanium-based enamel, and it is hygienic and has a long service life.

The loss of antifreeze is the minimum because it is closed to the atmosphere. Especially, it has higher performance and more convenient usage characteristics than the conventional float systems in terms of hot water comfort designed for areas where there is no water cut.

WORKING PRINCIPLE

Such systems are natural circulation and operate under pressure. It provides hot water as much as the network pressure. It works according to the closed containers principle and reaches to the network pressure during the first filling before the system starts to work. The system water capacity can be increased by connecting in parallel.

- All tanks are polyurethane insulated.

- All Collectors are Insulated Glass Wool.

- Mounting materials are not included in the package.(Pipe,Fittings,Glass Jar,Safety Group Etc ...)

- In Packing Systems Max Series S Collectors are Flat Glass,

- L Collectors are prismatic glass.

LIFOS 150 L

- 150 L Enamel Tank+Single L Case Aluminium/Copper/Copper Selective Collector+Stand in Set.

ASYA 200 L

- 200 L Enamel Tank+Double S Cases Aluminium Collector+Stand in Set

HISAR 300 L

- 300 L Enamel Tank+Triple S Cases Aluminium Collector+Stand in Set