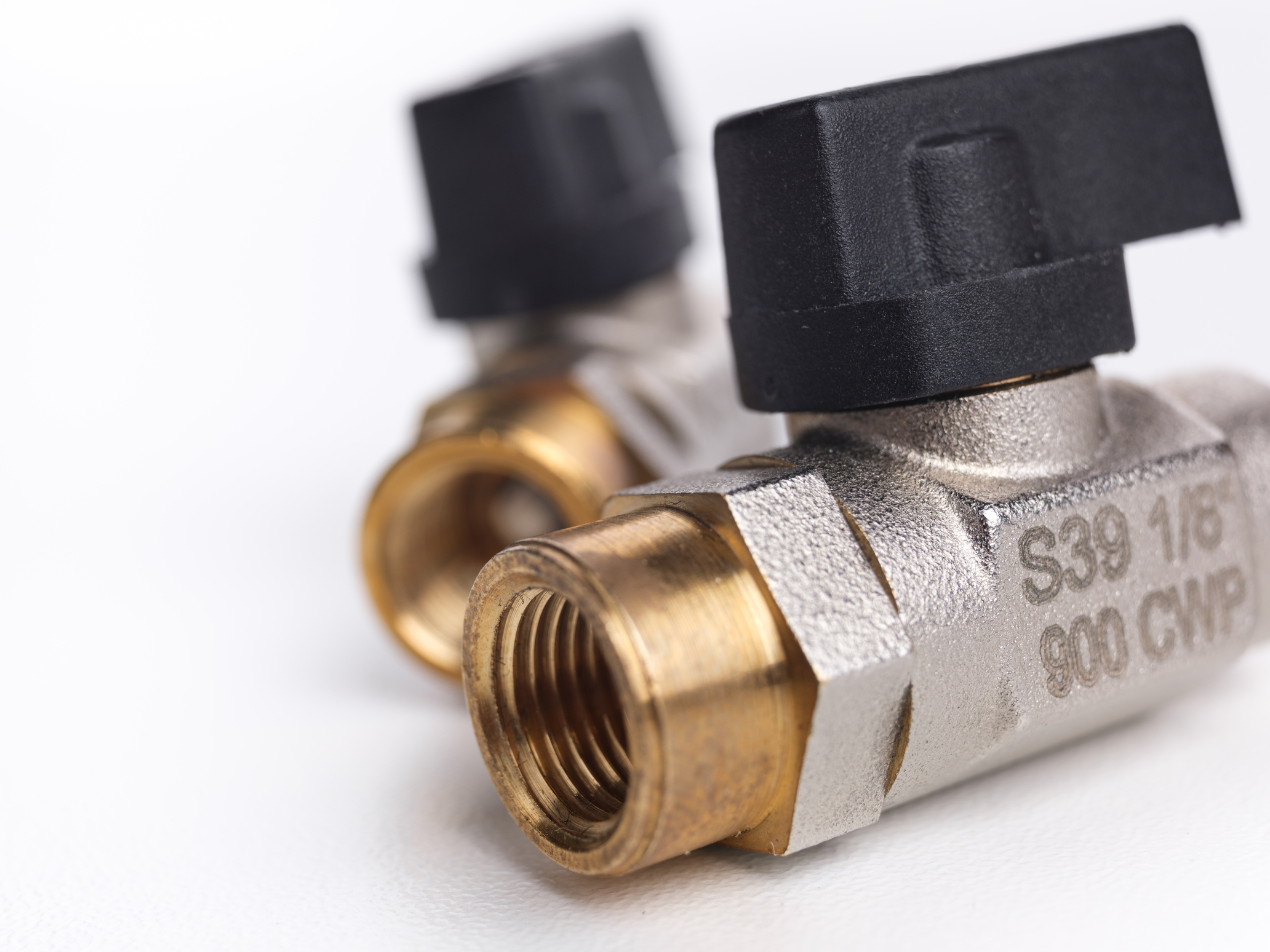

Description

Although the vast majority of ball valves are simple 2-port valves, there is a market for multi-port valves too. In certain types of industrial application they offer advantages over the straight 2-port products:

- A single 3-way valve can replace a tee and two 2-way valves, saving space and cost

- In certain cases 3-way valves can offer a safety advantage. For example, if there is danger in closing off both pump discharge valves at once, the use of a 3-way can automatically insure that one port or the other is always open.

3-way ball valves come in two different families – 2-seat designs and 4-seat designs. The mechanical function, the cost, and the market for the two types are quite different. 2-seat three-ways are not greatly more costly than ordinary 2-ways, and have enough applications to be of interest to distributors as a stocking item.

The s.7300 series has a ball seal at every port, and offers a wide variety of possible flow configurations. Positive shutoff can be achieved at any of the exiting ports.

By specifying the appropriate ball port configuration, the T-port design allows flow direction to be adjusted for virtually any situation and is ideal for mixing applications.

Our s.73 multi-port valves can reduce the number of valves required in piping systems and can significantly lower overall costs by replacing two or three conventional 2-way valves, eliminating excess fittings, saving space and simplifying automation. The valve can be purchased separately, with handle or with a RuB actuator already mounted.

The s.7600 series is the right choice for fluid diversion and is designed with robust maintenance-free components ensuring ease of operation and safety. With a simple 90° turn, you can divert flow from one downstream outlet to the other.

It combines traditional manual operation with modern automation. It is also very easy to convert from its sturdy lever handle to ISO 5211 actuator flange assembly.

It features low operating torque and a special wear reducing self-compensating

valve seat design that meets our 100,000 cycle life test requirement. The valve can be purchased separately, with handle or with a RuB actuator already mounted.