You can find the Interactive Hall Plan 2025 here.

Description

Save pump energy and ensure trouble free commissioning of the system with the PV Compact Valve

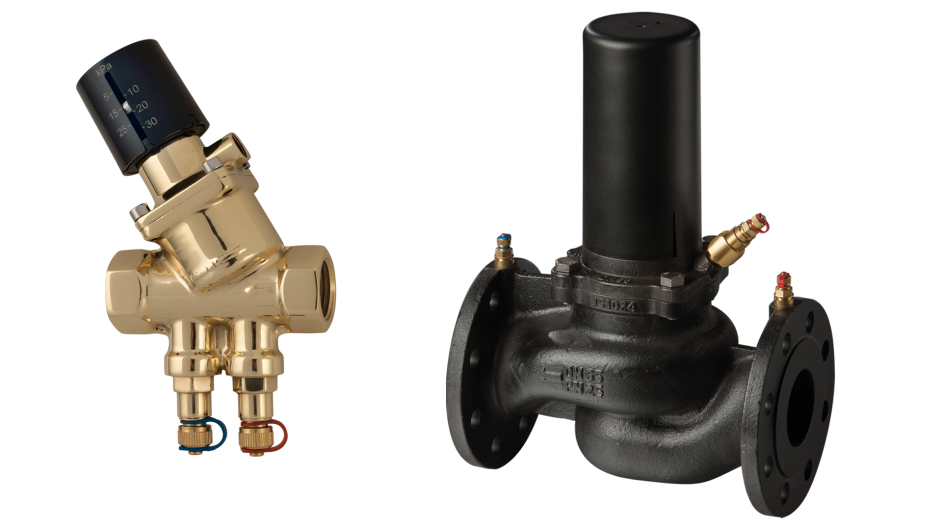

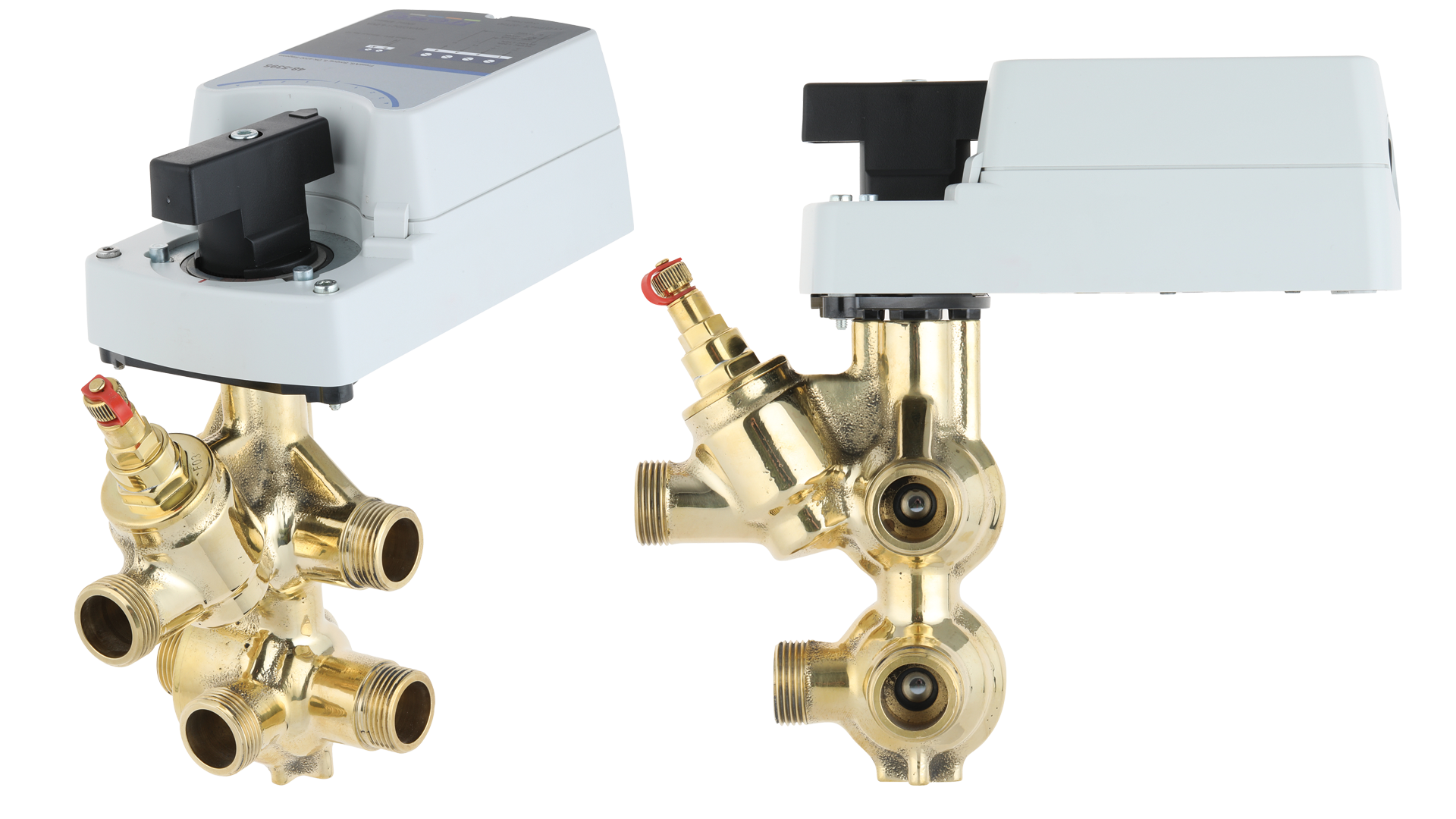

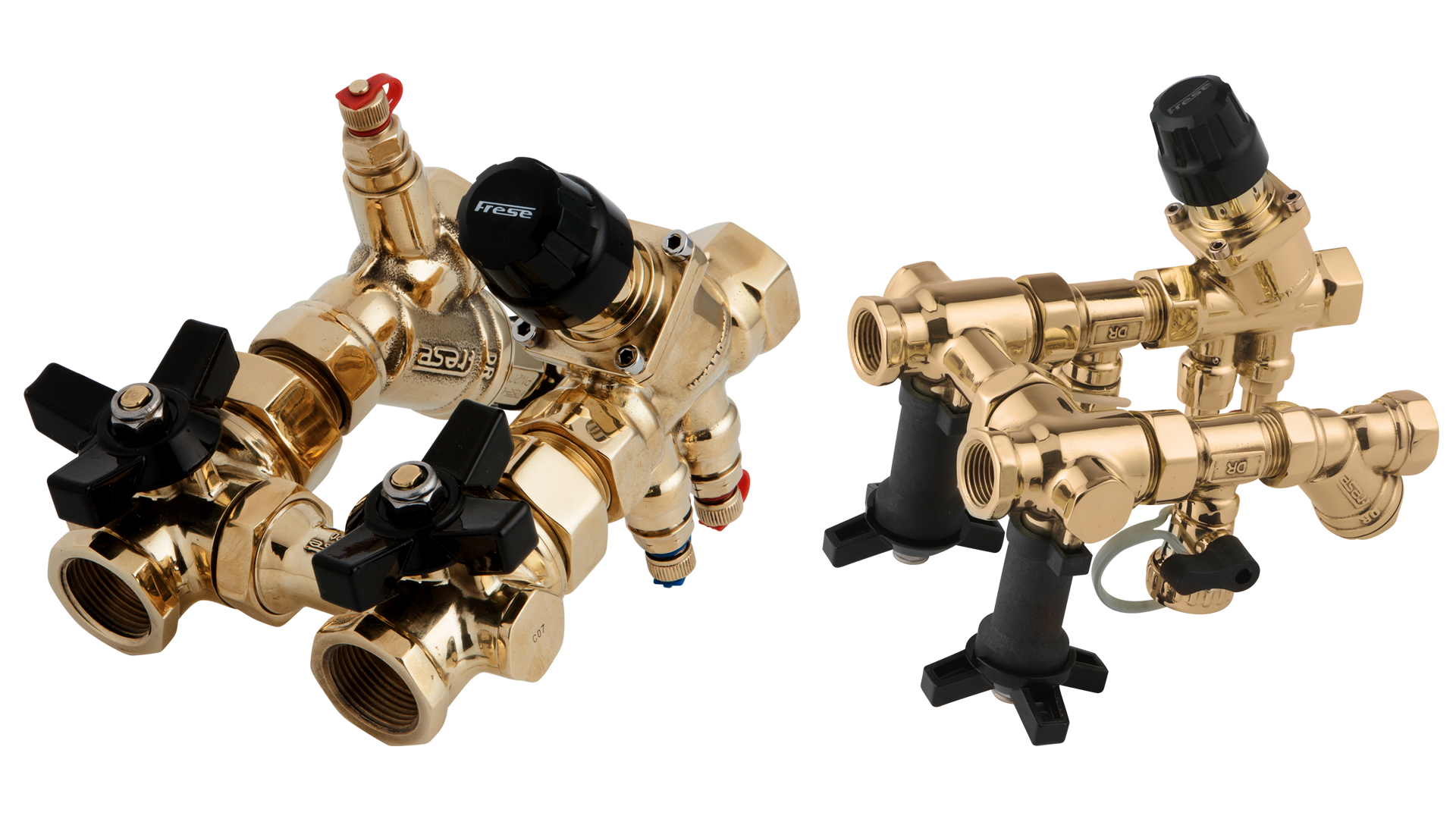

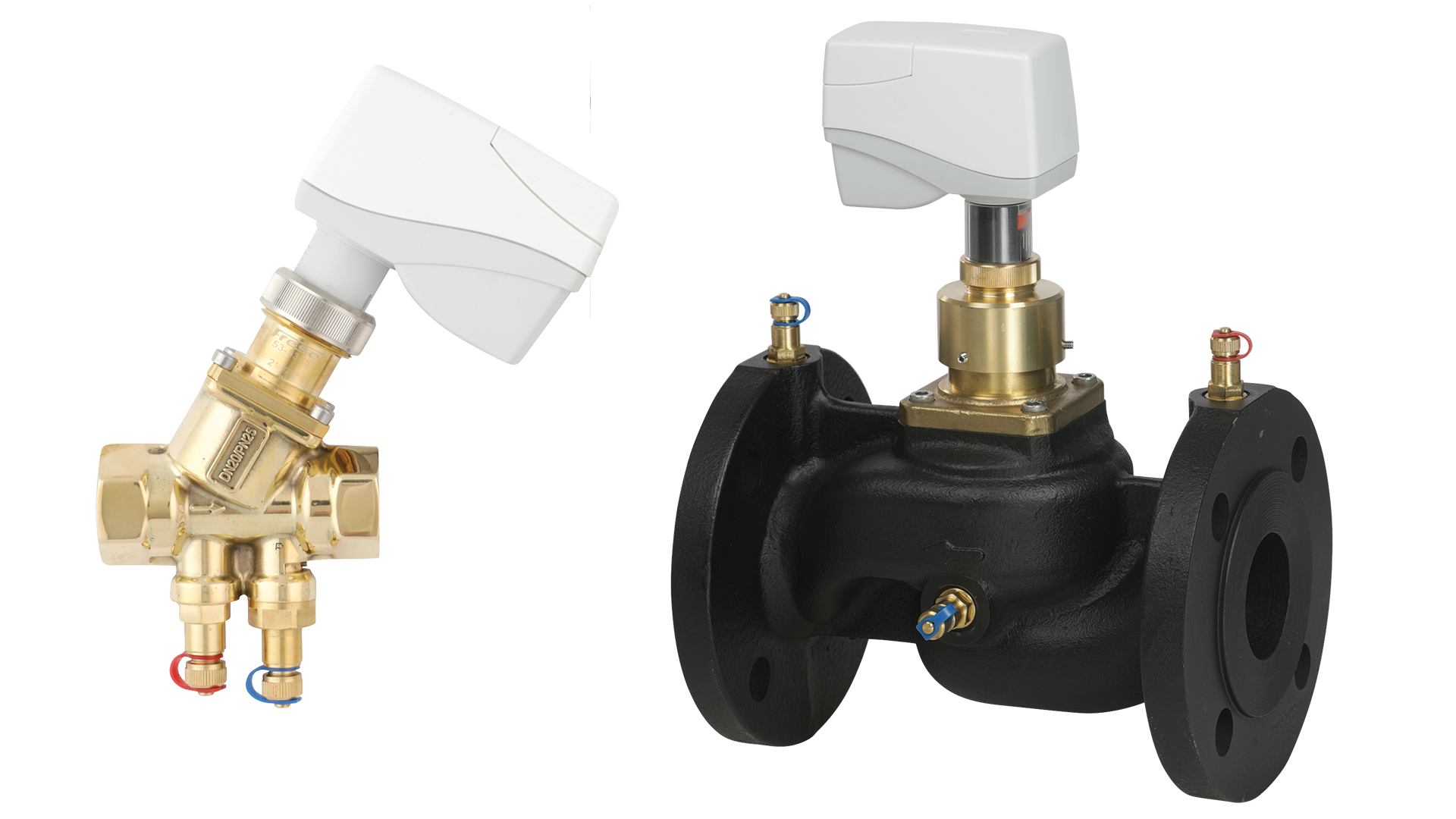

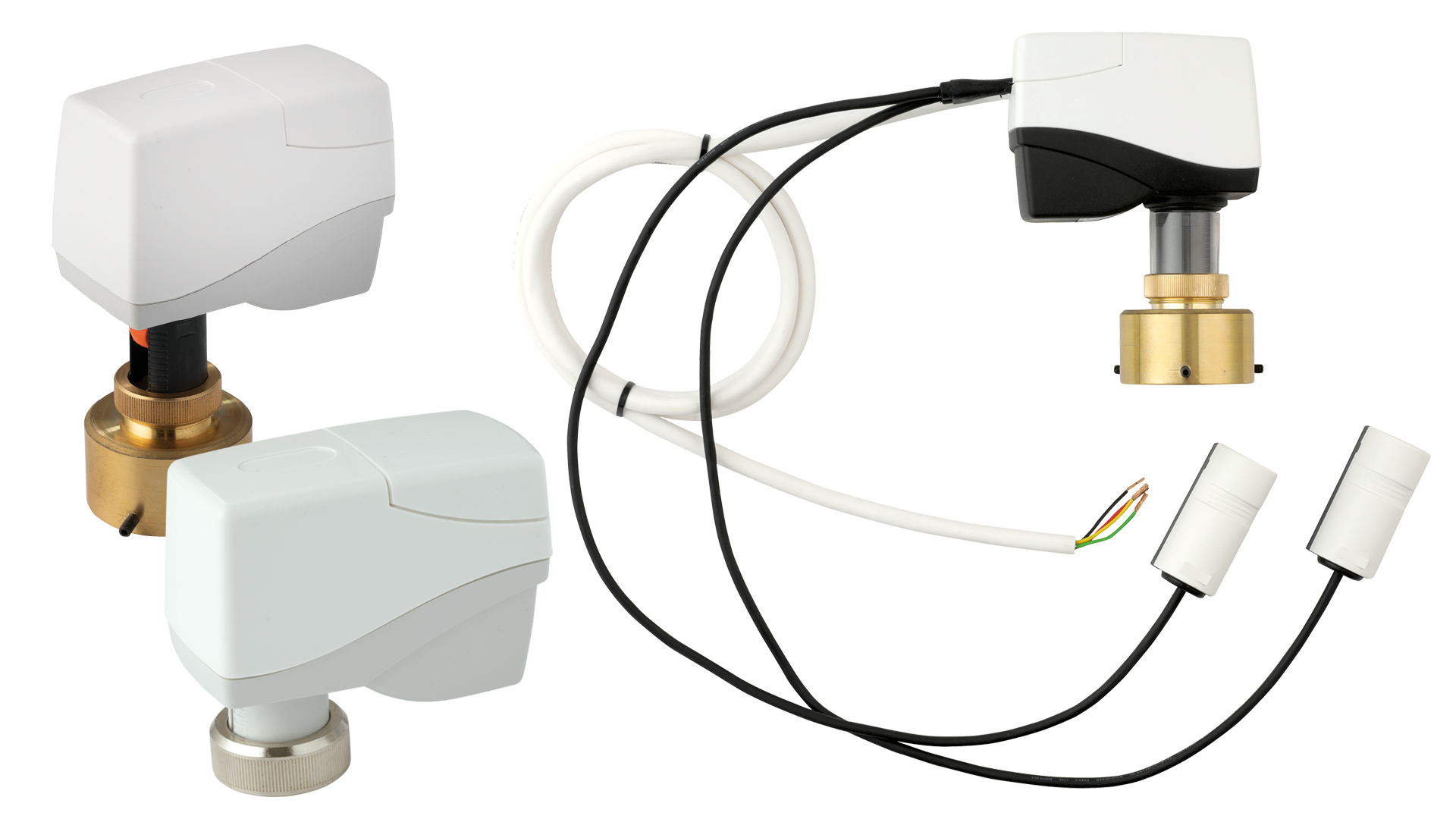

The PV Compact is a dynamic, adjustable differential pressure control valve designed using the common Frese COMPACT design platform seen in the popular OPTIMA Compact and SIGMA Compact valves.

By design, the PV Compact has a high Kv value which means it achieves the lowest pressure loss of any comparable differential pressure control valve contributing towards lower pump energy consumption and ultimately saving energy.

The compact design of the PV Compact makes installation easy, especially in systems with limited space availability and the external, tamper-proof pre-setting device on the valve allows the differential pressure to be set and adjusted on site with minimal disruption to the operation of the system.

The partner system valve for the supply side can be provided as part of the solution.

Setting the PV Compact is quick and easy using the simple and clear pre-setting device on the top of the valve - and with PV Compact, Spectrum-series it is even .

The required set point can be determined using the official Frese flow graphs or the Frese APP

Differential Pressure Control

Differential pressure control valves can be used in both domestic and commercial heating and cooling systems.

Due to fluctuating differential pressures, heating and cooling systems can often create noise as a result of the thermostatic control valves being unable to close fully.

Despite the more regular use of variable speed pumps in larger systems, the differential pressure is likely to increase when the system is in a partial load condition potentially resulting in an increase in system noise and the inefficient regulation of control valves.

A differential pressure control valve, like PV Compact or PV Compact, Spectrum-series ensures that the differential pressure across a circuit or load remains constant under all conditions,

protecting the thermostatic radiator valves and control valves from any increase in differential pressure thus ensuring good modulating control and a reduced risk of noise