You can find the Interactive Hall Plan 2025 here.

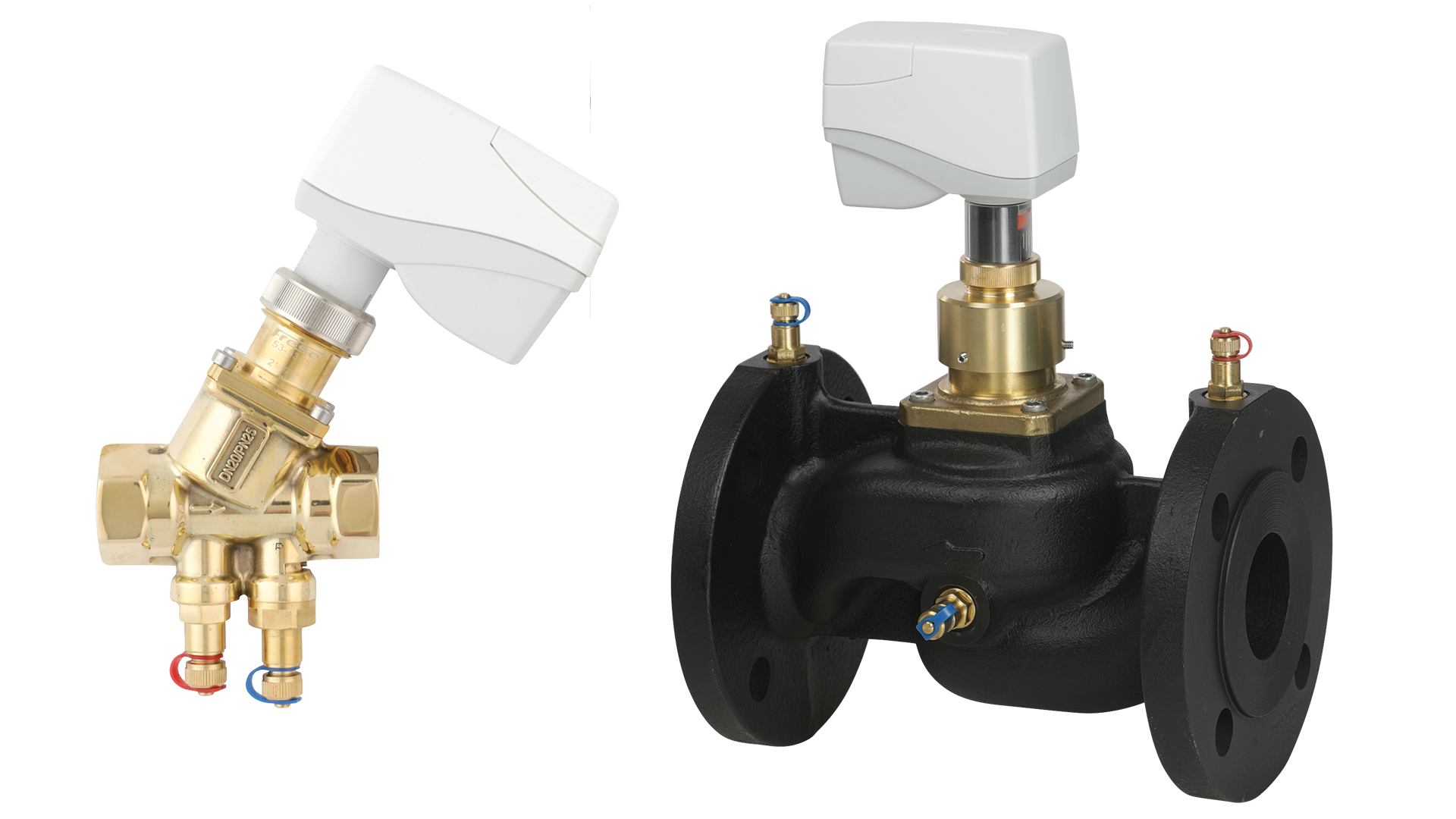

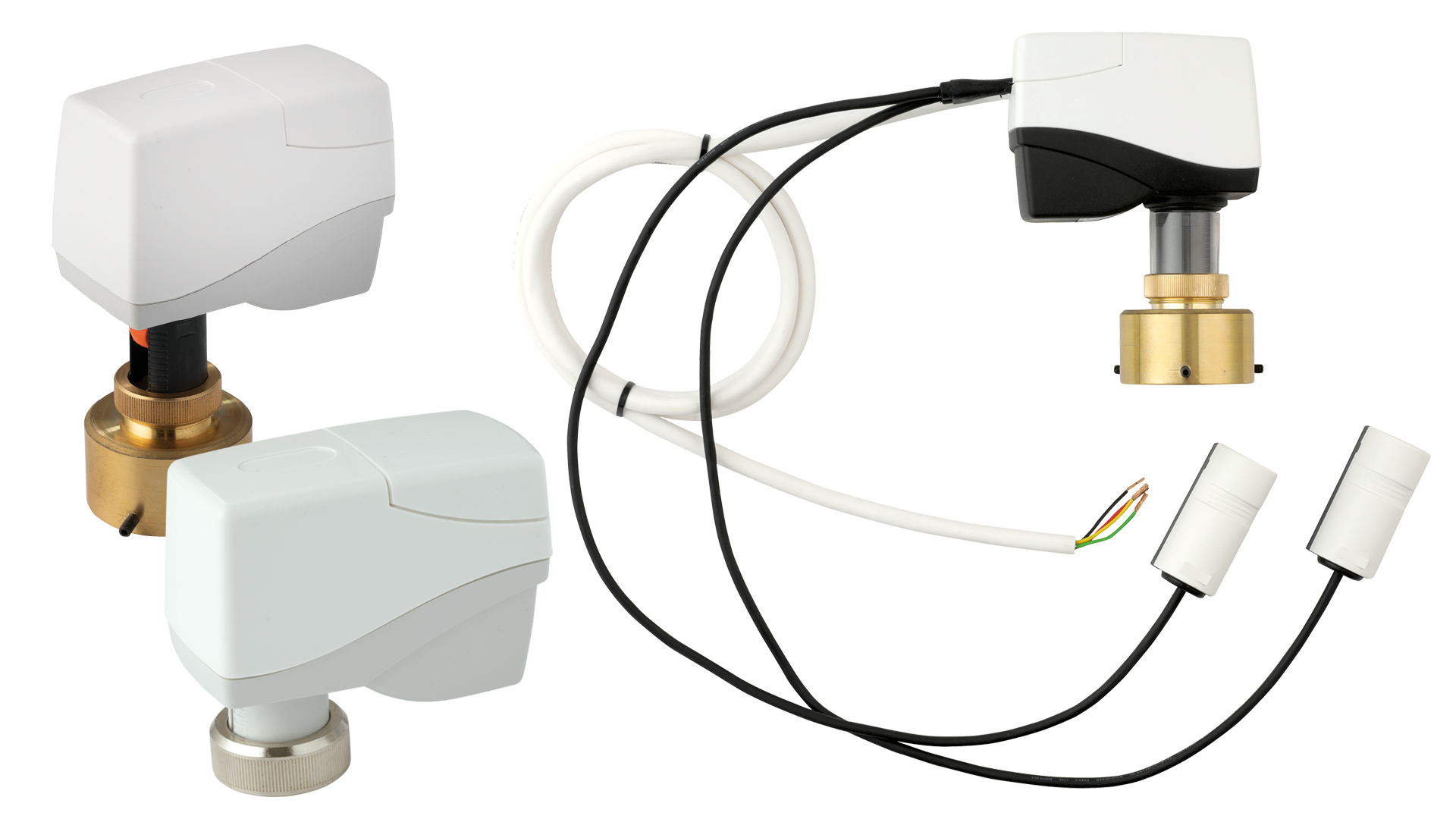

RadCon - Pressure Independent Radiator Valve

Description

Pressure Independent Radiator Valve

Frese RadCon is a pressure independent Radiator Valve (PIRV) for use in 2-pipe radiator systems.

Combined with the elegant thermostatic sensor head RadCon provides optimal comfort along with the highest energy efficiency and easy commissioning.

The valve can be preset from 20 l/h to 340 l/h (0.006 l/s to 0.094 l/s) and provides modulating control regardless of any fluctuations in the differential pressure of the radiator system.

It combines an externally adjustable presetting, a differential pressure controller and a modulating radiator valve.

100% control of the water flow in the building is achieved easily, while creating high comfort and energy savings. At the same time maximizing the ΔT is possible due to the increased system stability.

Benefits - Design

- Less time to define and select the right presetting. Just set the required flow for the radiator. No KV calculation needed

- Flexibility if the system is modified after the initial installation

Benefits - Installation

- No further regulating valves required in the radiator system when the differential pressure does not exceed70 kPa

- Minimized commissioning time due to automatic balancing of the system

- Simplified radiator system design

- Thermostatic sensor with M30x1.5 connection

Benefits - Operation

- High comfort for end-users due to high precision temperature control

- Anti-frost thermosatic head protects the system and reduces the risk of mould

- No flow noise due to the built in differential pressure controller in the valve

- No overflow through the radiator ensuring the optimal ΔT in the radiator system

- Easy maintenance - replacable internals

Features

- The constant differential pressure across the modulating control component guarantees 100% authority

- Automatic balancing eliminates overflows, regardless of fluctuating pressure conditions in the system

- Thermostatic sensor head with small dimension

- Differential pressure operating range up to 70 kPa

- Complete programme DN10-DN20

- Theft protection of thermostatic head