You can find the Interactive Hall Plan 2025 here.

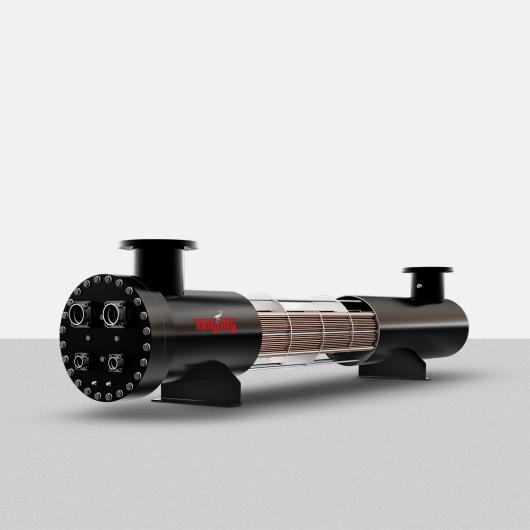

TANPERA TES Series Evaporators

TANPERA TES Series Evaporators

Description

The TANPERA TES Series Evaporators are a high-performance and durable heat exchange solution for HVAC and industrial cooling systems. Thanks to their high-efficiency heat transfer tubes and optimized design, they maximize the efficiency of the cooling process.

These evaporators, which can be produced with internally grooved copper tubes, stainless steel, or copper-nickel options, increase cooling capacity while minimizing energy consumption. Their compact design and modular structure allow for easy integration into various cooling systems. The advantages of easy maintenance and long-lasting use reduce operating costs and enhance system efficiency.

Key Advantages

✅ High Heat Transfer Efficiency: Delivers maximum performance with advanced internally grooved tubes.

✅ Energy Savings: Provides high cooling capacity with low energy consumption.

✅ Wide Application Range: Suitable for HVAC, food, pharmaceutical, metal processing, and many other industrial sectors.

✅ Durable and Reliable Structure: Ensures long-lasting use under industrial conditions.

✅ Easy Maintenance and Flexible Design: Easily integrated into different systems thanks to its modular structure.

Technical Specifications

📌 Heat Transfer Technology: Internally grooved copper tubes, stainless steel, or copper-nickel tube options

📌 Operating Pressure: 33 bar (refrigerant side), 11 bar (water side)

📌 Refrigerant Compatibility: HCFC, HFC, HFO (Standard R407C)

📌 Application Area: Industrial cooling, HVAC systems, chiller units

Application Areas

🏭 Food Industry: Cooling systems for the fresh and safe preservation of products.

🔧 Metal Casting and Processing: Control of high temperatures and cooling processes.

🏢 HVAC and Heat Pumps: Energy savings through efficient heat exchange.

🧊 Cold Storage: Reliable solutions for storing products under ideal conditions.

Optimize your cooling systems with the TANPERA TES Series Evaporators, save energy, and reduce operating costs!