Description

Aironn Axial Type Jet Fan Series

The Aironn Axial Type Unilateral Jet Fan Series is certified for 300°C for 2 hours and 400°C for 2 hours in compliance with EN 12101-3. Featuring airfoil fan blades with diameters ranging from 290 mm to 400 mm, the series delivers exceptional performance. The fans’ performance has been rigorously tested and validated in accordance with the AMCA 250-12 standard.

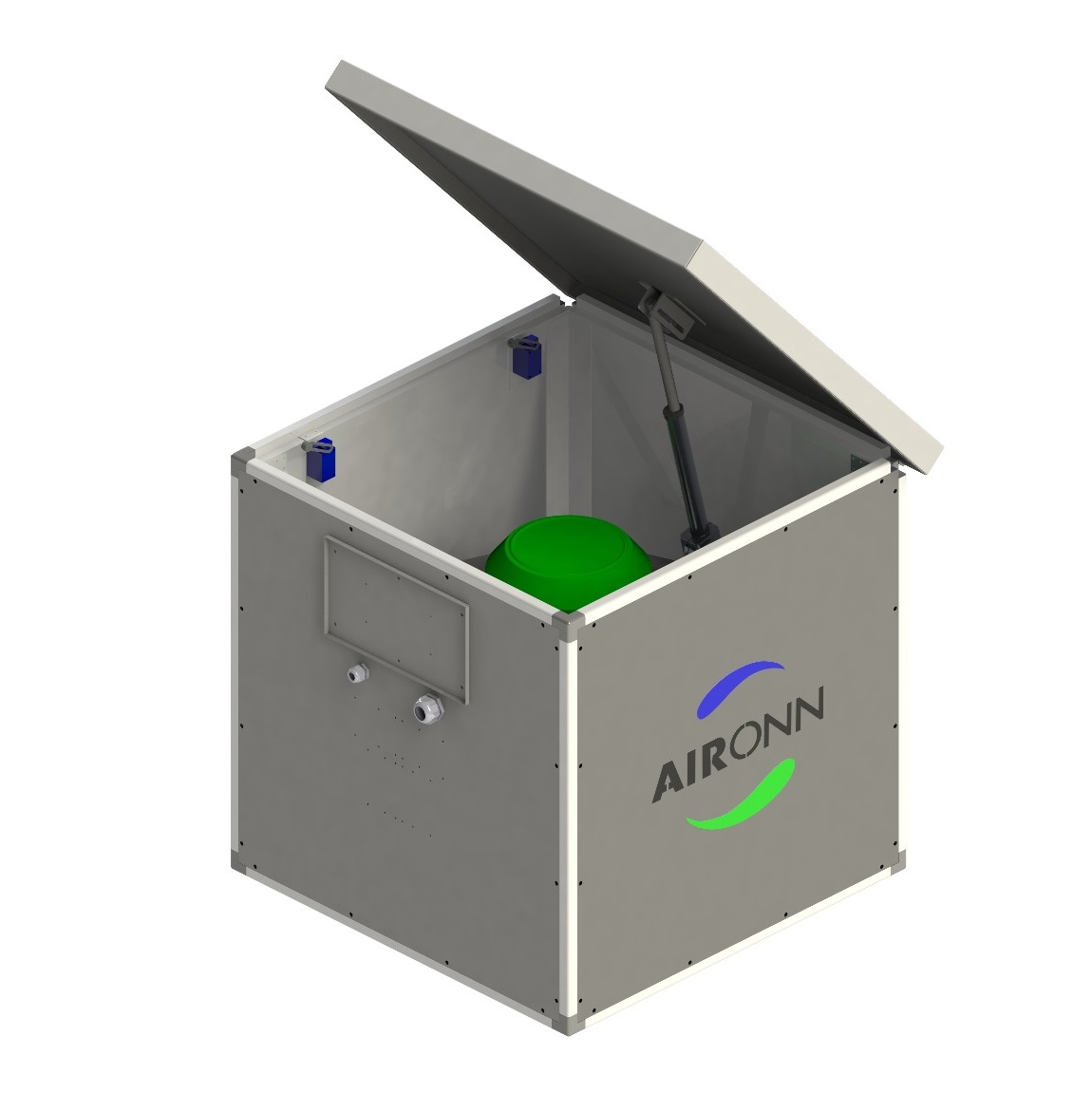

Fan Body

The fan bodies are constructed from high-quality galvanized steel, ensuring durability and corrosion resistance. Each unit comes equipped with a protection grill, which directs airflow on the discharge side and safeguards against debris on the intake side.

Fan Blades

The aerodynamic fan blades, made from ETIAL 171 aluminum alloy, are produced using the injection molding method. They are statically and dynamically balanced in compliance with ISO 1940/1-2003, guaranteeing stability and efficient operation.

Motor

The fans are powered by IP 55-rated motors with Class H insulation, available in both single-speed and dual-speed configurations. For added flexibility, single-speed motors can be adapted for use with inverters upon request. The sliding motor skid design ensures ease of maintenance and serviceability.

Electrical Components

Each unit features an IP 55-rated electrical terminal box, securely housed within the galvanized steel body for enhanced protection and reliability.