You can find the Interactive Hall Plan 2025 here.

Anti-Freeze Valve

Anti-Freeze Valve

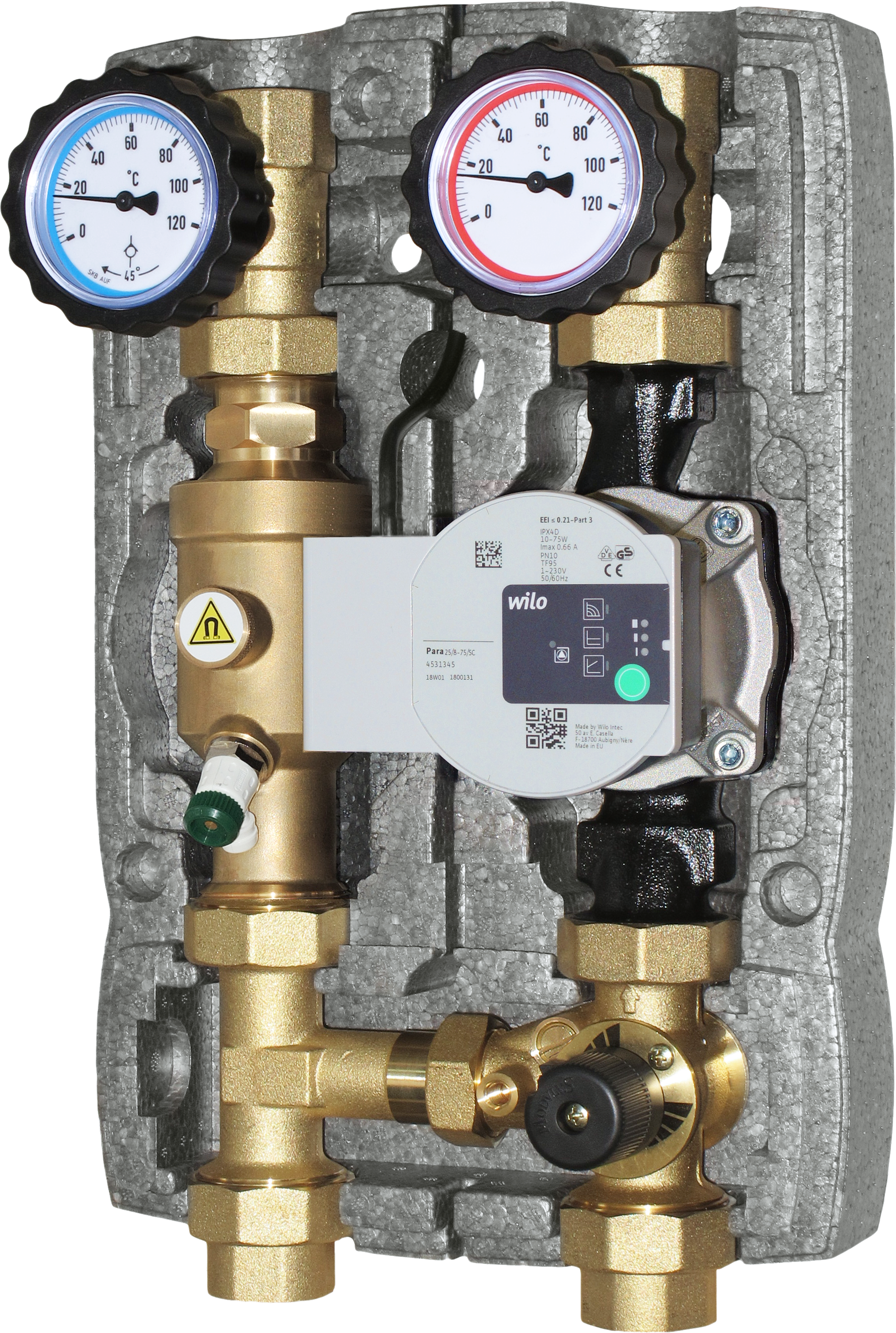

Description

Anti-freeze valve for heating/cooling systems with heat pump.

The anti-freeze valve allows to protect the pipes and the heat pump from failures caused by freezing of the water inside them.

In case of shutdown of the system during the winter season, if the water temperature drops down to +3°C, the valve starts to open allowing a discharge, initially modest: the outflow draws the water from the side of the circuit inside the building, having a higher temperature, thus preventing the formation of ice.

If the discharge continues due to cold temperatures, in the absence of a filling group, the internal pressure of the circuit runs out and tends to reach atmospheric pressure, thus making the outflow impossible: a vacuum breaker valve present in the upper part of the valve body intervenes to allow the intake of air, allowing water drainage to continue.

The presence of an automatic circuit filling unit is recommended it which, by restoring the pressure in the circuit, will bring the anti-freeze valve back to normal working conditions and the system will be able to restart autonomously.