You can find the Interactive Hall Plan 2025 here.

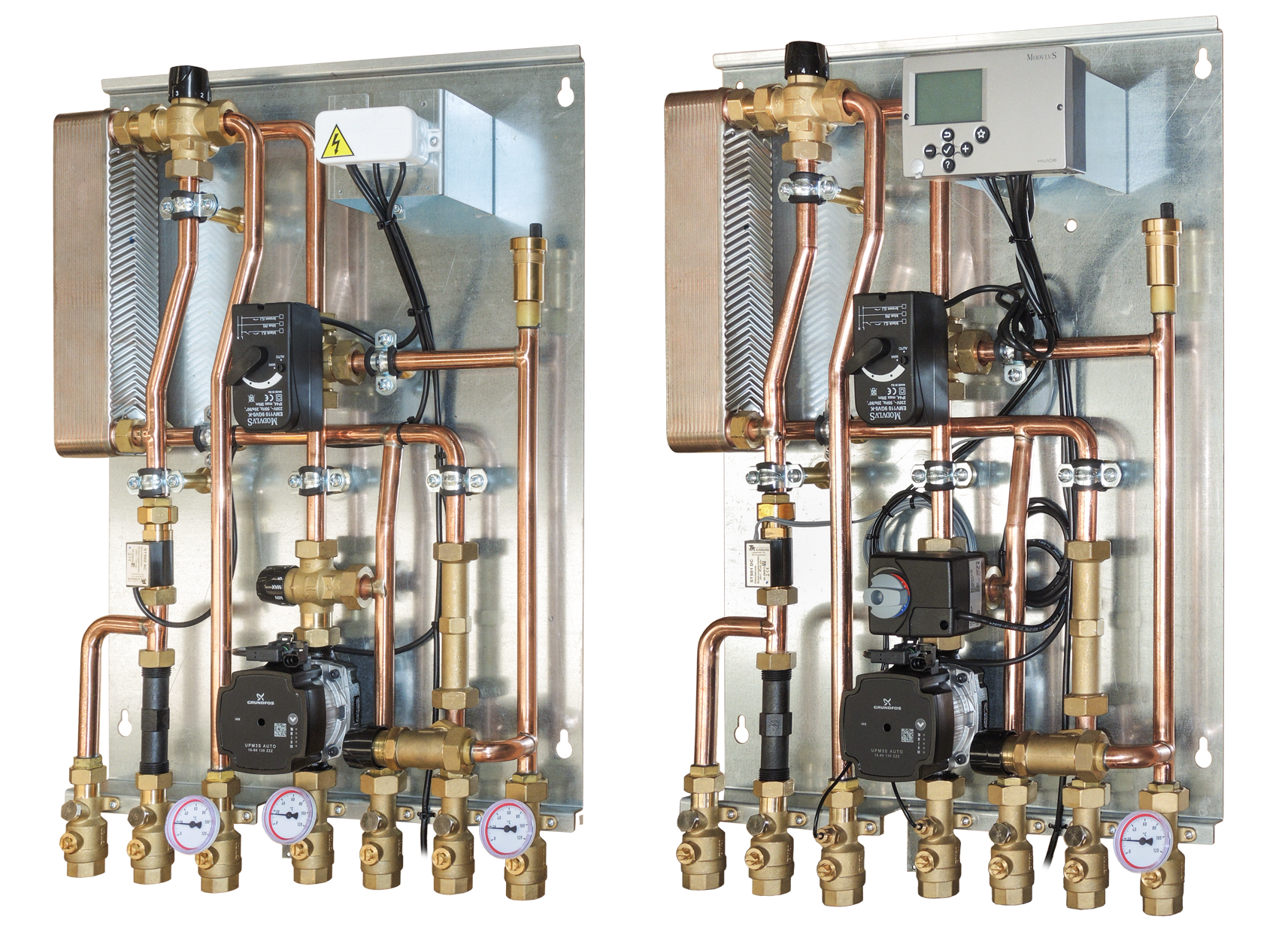

ModvlvS DN25 M2 MIX33

ModvlvS DN25 M2 MIX33

Description

ModvlvS DN25

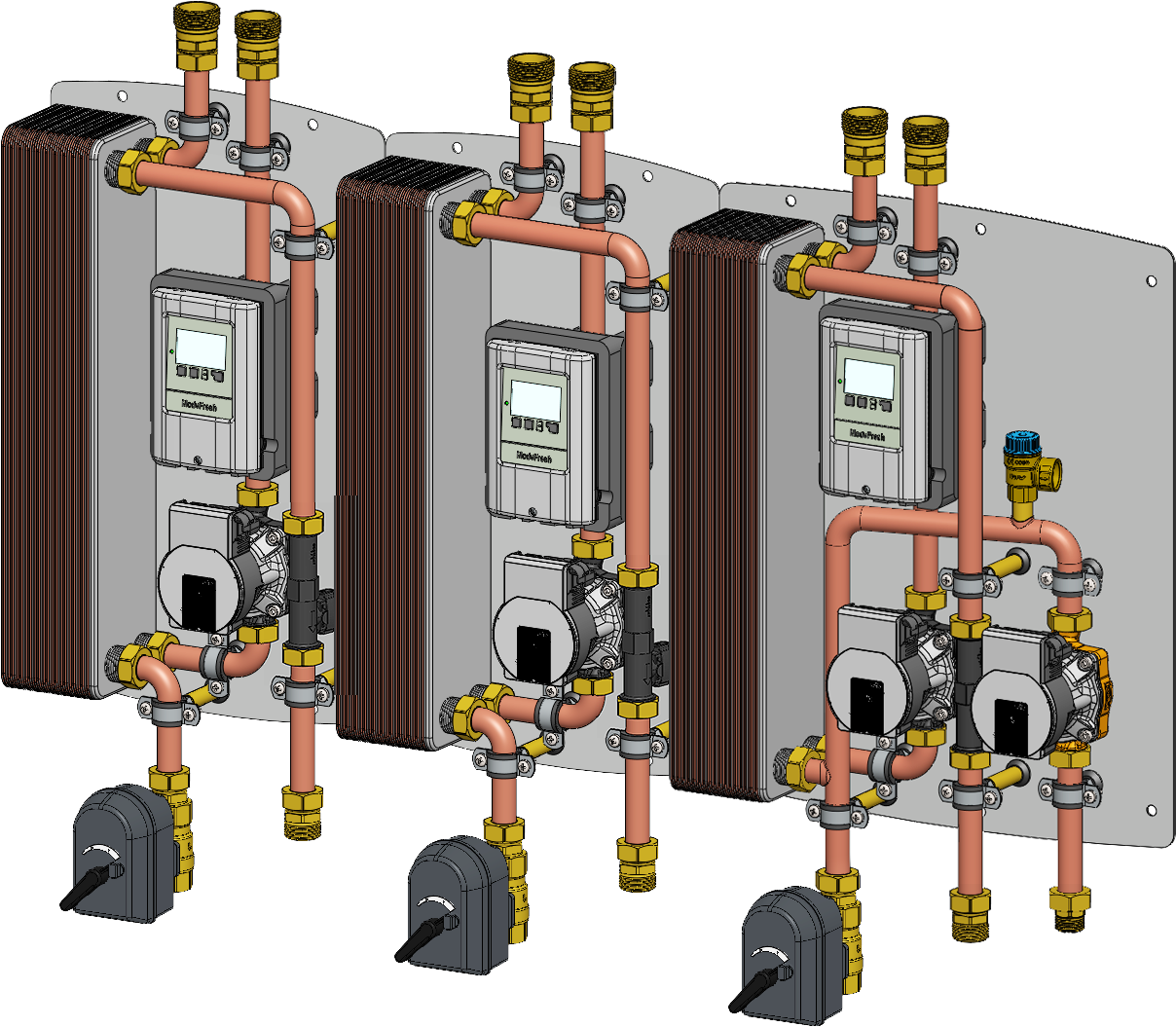

The ModvlvS DN25 series includes a complete range that meets all the installation needs with specific models: middle and low temperature heating systems, energy metering, cooling systems; everything with the possibility of a management control by means of climatic controllers even built-in the pump unit. DN25 pump units can be connected to heating systems with powers up to 50 kW, with a very low energy consumption ensured by high efficiency synchronous circulating pumps. The connections to the circuit or to the manifold are made with a 1” female thread. Moreover the pump units of M3 version are equipped with a by-pass balancing valve that allows an accurate regulation of the differential pressure of the circuit. The range is completed by various accessories and components: manifolds, fittings, safety units, mixing valves and servomotors.

M2 MIX33

2-WAY PUMP UNIT WITH 3-WAY MIXING VALVE

WITH BUILT-IN BY-PASS

The unit for 1” (180 mm) circulating pumps consists of:

Supply

Connection.

3-way mixing valve with adjustable by-pass. Through the by-pass (adjustable from the front part) it is possible to mix on the supply line a quantity of water coming back from the return line of the system.

High efficiency synchronous pre-wired circulating pump (for the models that include it).

Flanged ball valve supplied with in-handle thermometer (red ring, range 0°C-120°C).

Return

Flanged ball valve with 20 mbar check valve (which can be excluded by rotating the handle by 45°) supplied with in-handle thermometer (blue ring; 0°C-120°C).

Magnetic filter (in the models where it is present)

“T” Connection for mixing valve.

Connection.

Integrated by-pass

The by-pass integrated into the 3-way mixing valve ensures a recirculation inside the installation, even when the mixing valve is fully open. Through the by-pass, a fixed percent of the mixing can be set, in the case when the flow through the mixing valve is not sufficient. In case of a bad working of the system causing an increase of the temperature of the installation, the recirculation through the by-pass allows a decrease of the water temperature in the underfloor installation, by mixing the warm water of the return circuit with the hot water of the supply circuit, reducing possible damages. M2 MIX33 pump units are supplied with the recirculation by-pass fully open.