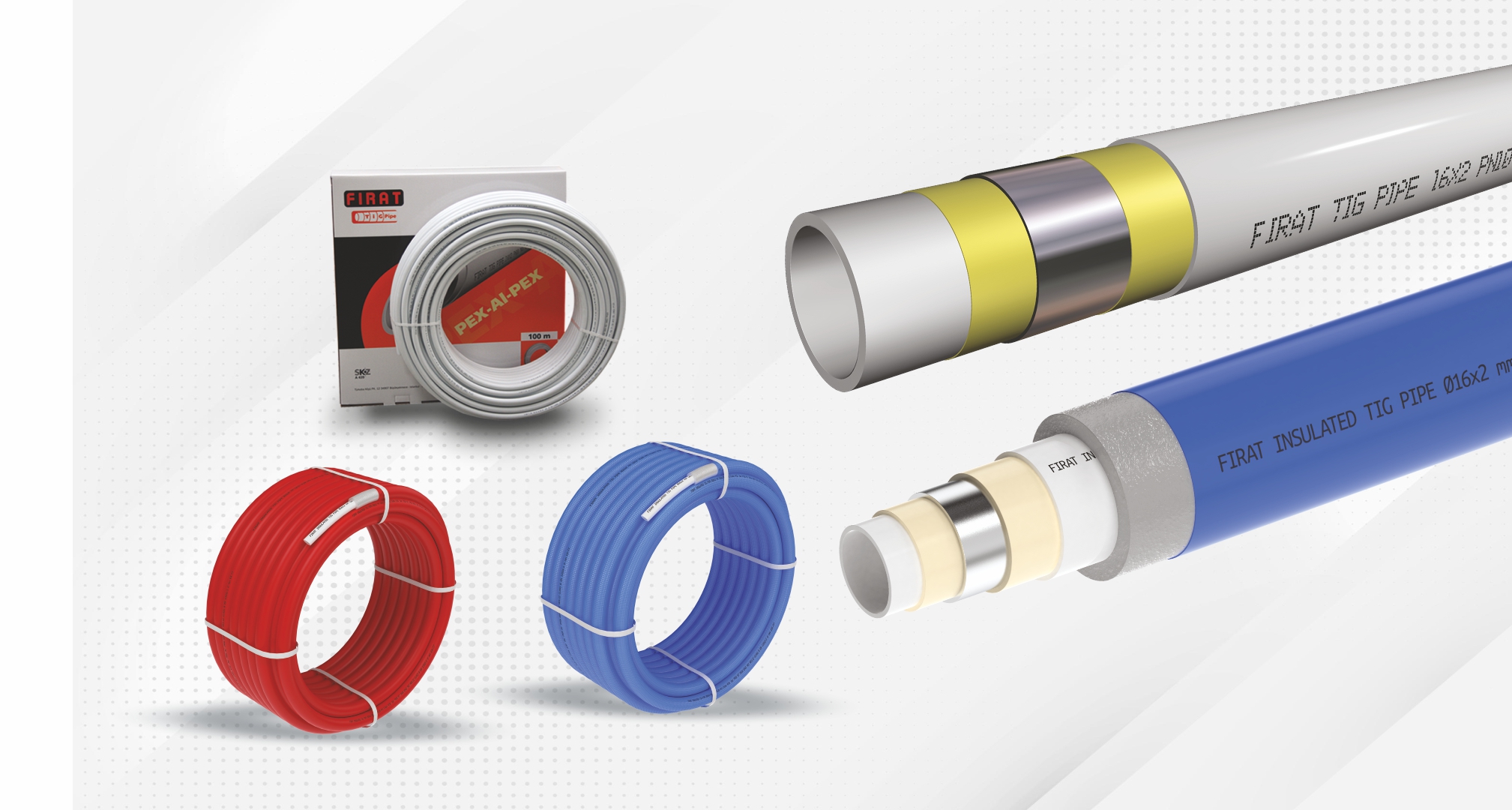

Pex-Al-Pex&Pert-Al-Pert Multilayer Pipes

Description

TIG Pipes are used for warm and cold water systems, radiator systems, pressured air installations, transmission of cooled fluids, inner-building fresh water systems and floor heating systems. TIG Pipes are produced through a special technology combining the superior features of plastic and metal materials. While the inner and outer layers of TIG Pipes are made of polyethylene, aluminum is used for the production of the middle layer.

The name of this special pipe is derived from the special method used to produce it. Aluminum layer is twisted over the polyethylene layer (its molecule structure includes cross linked PE-Xb) and these two materials are then fixed with arc welding (Tungsten Inert Gas).

Inner and outer surfaces of TIG Pipes are formed by PE-Xb layers which are resistant to high temperatures, hygienic,, resistant to corrosion and impacts taking root of external influences, very smooth and which are preventing sedimentation, providing excellent isolation.

In addition to these, a special adhesive and method is used for fixing the inner and outer PE-Xb layers with excellent properties to the aluminum layer.

Welding Technology Used for the Aluminum Layer of Tig Pipes

The welding technique named as Tungsten Inert Gas has been considered to be a very important technological development by the plastics industry in recent years. This method includes bending the aluminum layer onto the PE-Xb, inner layer and then fixing these two layers through arc butt welding. This technology surpasses the old technologies like overlapping in terms of life time and reliability.

Properties of Aluminum Material

Middle layer of TIG Pipes is made of aluminum. After being coated on the inner PE-Xb layer, the aluminum material is then fixed to the structure through the superior technical properties of Tig welding.

Advantages Provided by Aluminum

- Thanks to the aluminum layer taking place in Tig Pipes, oxygen diffusion from the outer medium to the water inside the pipe is prevented and no oxidation is observed on the metal parts of the system, as a result.

- Thanks to the aluminum layer, Tig Pipes can be very easily buckled and they also keep the new shape formed. As a result of their ability to be buckled at 6 times of its diameter, savings in fitting consumption can be obtained.

- Thanks to the low thermal expansion coefficient of the aluminum layer, no sagging is observed at on-wall Tig Pipe applications.

Address

Firat Plastik Kaucuk San. ve Tic. A. S.

Türkoba Mah. Firat Plastik Caddesi 23

34537 Büyükcekmece/Istanbul

Türkei

Telephone+90 212 866 42 93

Fax+90 212 859 05 00

Discover more from us