You can find the Interactive Hall Plan 2025 here.

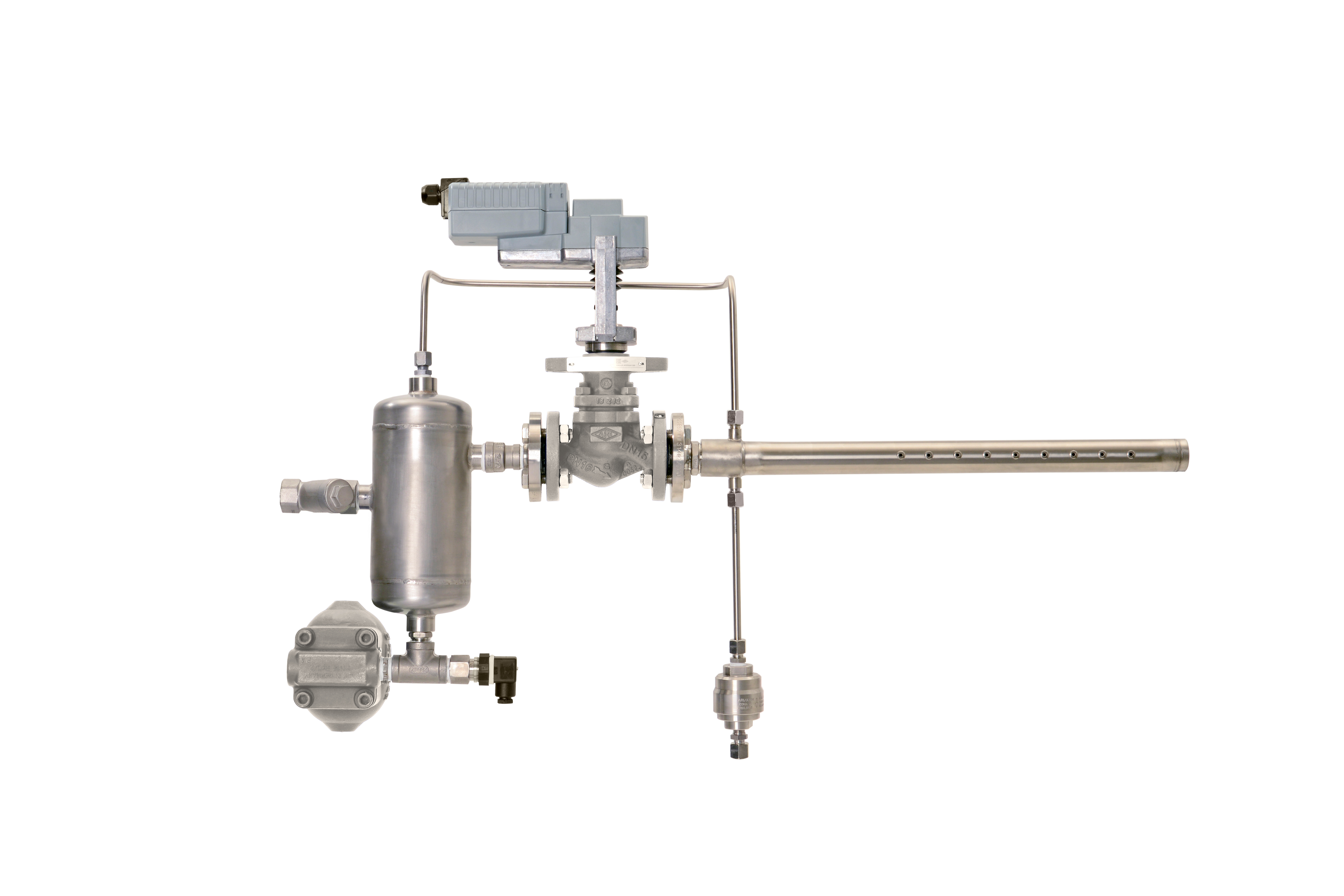

FlexLine Plus and Process heater steam humidifiers

FlexLine Plus and Process heater steam humidifiers

Description

FlexLine Plus and Process for precision and process humidification.

A stable and controlled room climate is indispensable for many production processes. Fluctuations in air humidity and especially excessively dry air have a massive influence on the raw materials used, on their processing capabilities and thus ultimately also on the quality of the end products.

HygroMatik FlexLine Plus and Process heater steam humidifiers have been developed especially for the use in precision and process humidification, in sensitive areas of industrial production as well as for the stabilisation of the relative air humidity in laboratories and research facilities.

All advantages at a glance.

Advantages for the operator

- Precise control and reliable stabilisation of air humidity in the ambient and room air

- Increased process efficiency by reducing errors and failures

- Increased productivity and product quality

- Protection against dangerous electrostatic discharges

- Healthy and pleasant working environment for employees

FlexLine Plus and Process

Maximum flexibility that pays for itself.

As part of the FlexLine series, a new generation of steam humidifiers, the HygroMatik FlexLine Plus and Process units can be flexibly expanded from a basic model with appropriate options. Every humidifier can thus be optimally adapted to the individual requirements of a project.

Advantages for project planning

- Reduction of installation complexity by means of individual pre-configuration ex factory

- Optimum connection to the building management system

- Optional Modbus or BacNet

- Retrofittable with optional expansion options

- You only invest in the functions you really need

The optimal humidification performance.

Equip the HygroMatik FlexLine Plus and Process with the power you need for optimum humidification performance. There are seven output classes from 5 to 50 kg/h steam output in one unit size to choose from. In addition, individual performance adjustments can be programmed both at the factory and on site. Higher humidification performance is achieved by connecting units together.

Many options for individual configuration.

The respective basic model of the FlexLine is the basis for all other configuration options. Thanks to their individual equipment, HygroMatik FlexLine Plus and Process can be adjusted to the requirements of various industrial and process control applications and equipped with a wide range of options so that they optimally meet every project requirement (e.g. HyCool – integrated waste water cooling). These options can also be retrofitted as needed.

The robust stainless steel cylinders – high quality and hygienically clean.

In some application areas, such as hospitals or other medical areas, stainless steel cylinders are sometimes preferred. The stainless steel cylinders of HygroMatik FlexLine Plus and Process generate hygienic, mineral free steam and are designed accordingly for these applications.

- The stainless steel split cylinders can be opened easily and

cleaned without chemicals - The robust heater mounting allows a simple and fast installation

and removal of the heating elements - Available in two cylinder sizes with volumes attuned to the

humidification capacity