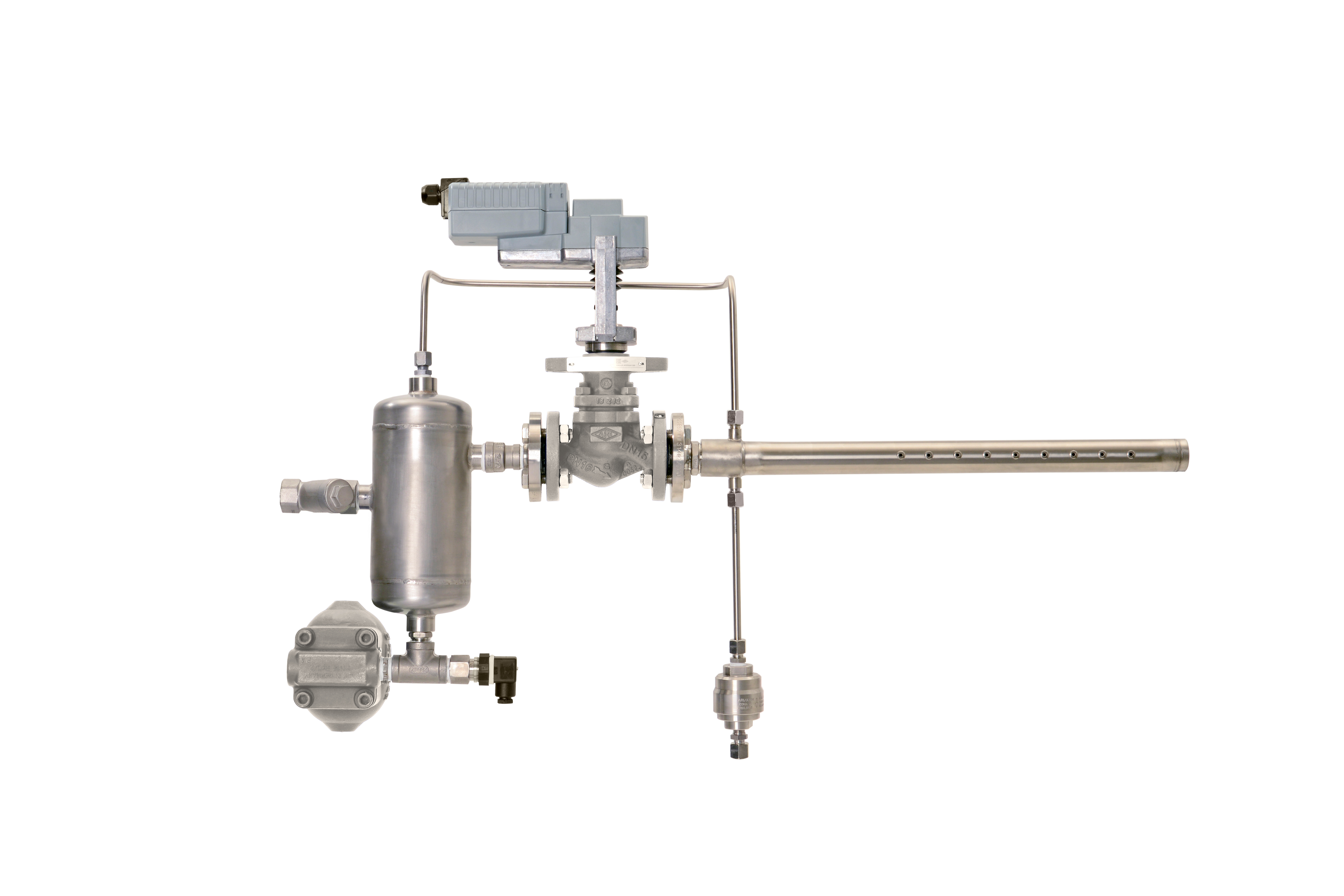

LPS und HPS adiabate Nieder- und Hochdruckdüsensysteme

Description

LPS und HPS. Höchste Leistung unter Nieder- oder Hochdruck.

Die adiabaten Nieder- und Hochdruckdüsensystem LPS und HPS befeuchten die Luft in Klima- und Lüftungsanlagen. Sie überzeugen durch eine sehr hohe Befeuchtungsleistung bei besonders niedrigem Energiebedarf, einem Wirkungsgrad von bis zu 98 % und höchster Regelgenauigkeit.

Hygienisch.

Während andere Systeme nur einen Tropfenabscheider verwenden, sind LPS und HPS mit zwei leicht herausnehmbaren, reinigbaren Tropfenabscheidern aus hochwertigem, inertem Metallgeflecht ausgestattet. Diese sorgen für besonders zuverlässige Aerosol-Abscheidung und höchste Hygiene.

Ausschließlich das eingesetzte vollentsalzte Wasser ohne Zusatzstoffe gelangt in die Atemluft. Die Systeme enthalten keine porösen, wasserspeichernden Komponenten. Stehendes Wasser wird effektiv verhindert und bei Stillstand werden die Systeme automatisch entleert. Im gesamten LPS und HPS kommen ausschließlich inerte (d.h. chemisch reaktions-neutrale) Materialien mit dem Befeuchtungswasser in Berührung. Dadurch kann auf chemische oder biologische Desinfektionsmittel völlig verzichtet werden. Auch die teure Entsorgung von kontaminierten Komponenten als Sondermüll entfällt. Die Hygiene-Konformität wurde vollumfänglich durch den TÜV Nord zertifiziert.

Durch den völligen Verzicht auf chemische oder biologische Desinfektionsmittel entfällt das kostenintensive ständige Überprüfen und Nachfüllen von keimvernichtenden Mitteln. Das spart Geld und ist gut für die Umwelt.

Das LPS und das HPS gewährleisten eine schnelle Amortisation und eine lange Lebensdauer durch hochwertige Komponenten.

Zertifiziert.

Die Systeme entsprechen den deutschen Normen VDI 6022-1 und 3803-1.

Ein anerkanntes unabhängiges Prüfinstitut hat die Konformität mit den Richtlinien und dem anerkannten Stand der Technik untersucht und bestätigt (VDE Prüfbericht Nr. 802300-3980-0001/85569). HygroMatik LPS und HPS sind vollumfänglich mit dem Prüfzertifikat Hygiene-Konformität für den Klimabereich und den Krankenhausbereich und CE zertifiziert.

Präzise Steuerung.

Das LPS wird über ein klares LED-Display und das HPS über ein kapazitives 3,5" Touch-Display gesteuert. Beide Steuerungen ermöglichen genaueste proportionale Befeuchtungs-Regelung mit einer Exaktheit von +/- 1%. Die Displays zeigen alle Meldungen und Betriebsdaten an und verfügen über eine komfortable menügeführte Bedienung. Ständige Sensorüberwachung aller Systemkomponenten und -funktionen gewährleistet höchste Betriebssicherheit.

Kurze Befeuchtungsstrecke.

Hochpräzise Edelstahlhochdruckdüsen erzeugen feinsten Nebel, der in der Gerätekammer von der Luft besonders schnell aufgenommen wird. Zudem vermischt die Vortex-Wand aus hochentwickelten Vortex-Modulen auf kürzester Befeuchtungsstrecke die Kanalluft mit dem Zerstäubungsnebel. Durch die schnelle und effiziente Absorption entsteht so gut wie kein Verlustwasser – das spart VE-Wasser.

Durch den optimalen Wirkungsgrad bieten die Systeme kurze Befeuchtungsstrecken bis zu 0,9 m. Außerdem passen LPS und HPS durch ihren modularen Aufbau in jeden Klimakanal – das spart Kosten bei der Planung und beim Einbau.

Adiabater Kühleffekt.

Die Verdunstung des feinen Nebels kühlt die Luft adiabatisch ab. Bei Fortluftkühlung im Sommer kann die Auslegungsleistung ihres Kühlregisters bis zu 1/3 reduziert werden. Das spart Kosten bei der Investition und im Betrieb.

Energiesparend und umweltbewusst.

Die Niederdruckzerstäubung bei 5 bis 15 bar sowie die Hochdruckzerstäubung bei 25 bis 75 bar bieten eine hohe Befeuchtungsleistung bei niedrigem Energiebedarf. Die durchdacht konzipierten Systeme erlauben durch den hohen Wirkungsgrad und die exakte Regelbarkeit eine besonders effiziente Nutzung des eingesetzten vollentsalzten Wassers und sind durch die minimale Verlustwassermenge äußerst wassersparend.

Die Befeuchtung mit vollentsalztem Wasser verhindert effektiv Kalkniederschlag und gewährleistet besonders geringen Wartungsbedarf.

Discover more from us