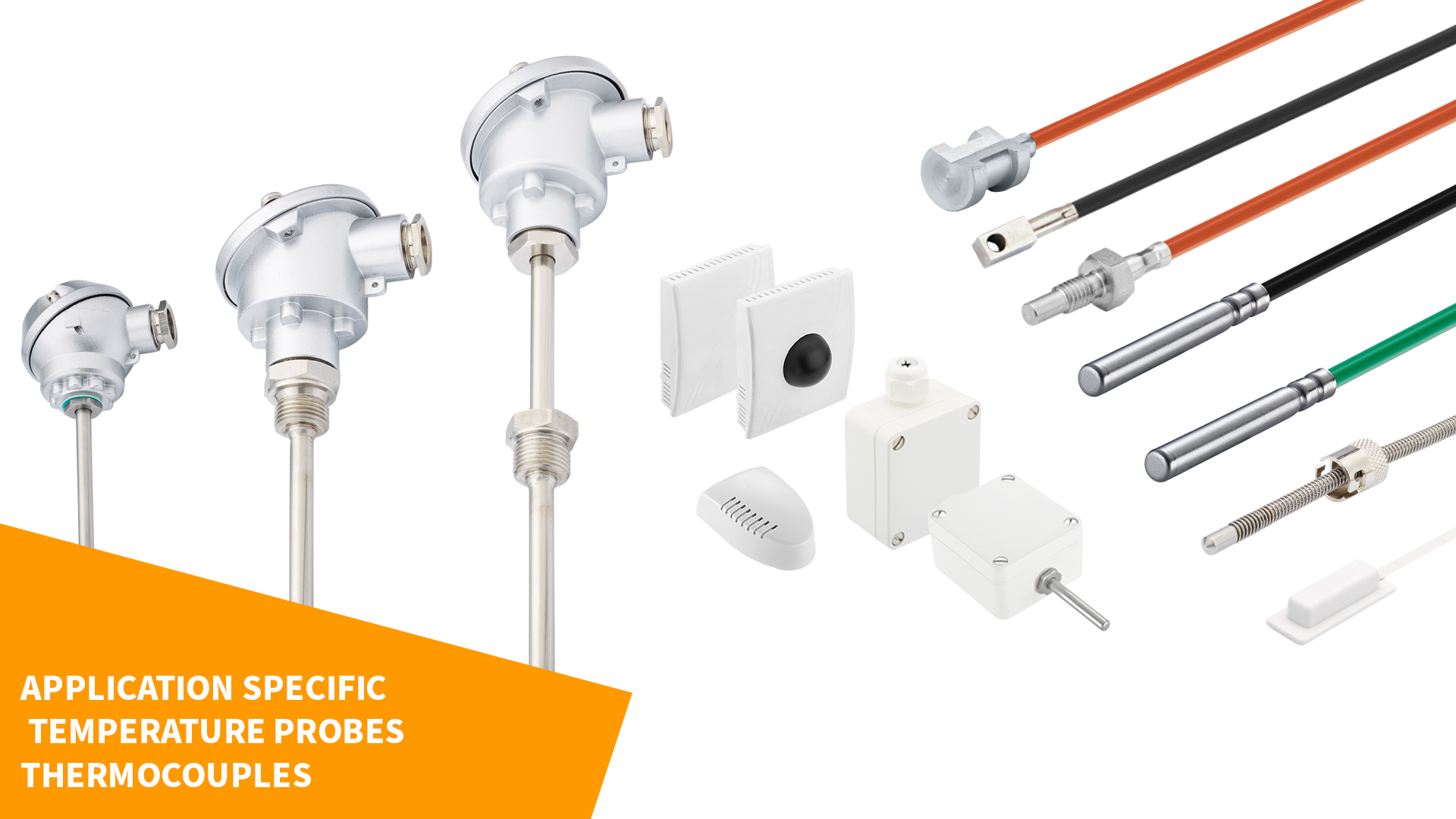

Temperature probes for heat pumps

Description

The most demanding applications for temperature probes in the heating industry are in heat pump applications.

Large temperature ranges, fast temperature changes, ice, rain, sun and high humidity alternate, so that the temperature probes are exposed to extreme environmental influences.

A specific sensor design optimised for each application is therefore necessary to be able to cover the applications in heat pump heating systems really reliably and with long-term stability.

Testo Sensor GmbH develops, qualifies and manufactures temperature probes for heat pumps in very large quantities. This is what distinguishes our probes:

Robust sensor design: resistant to humidity, ice, water, temperature changes and vibration.

As a result, the probe operates safely, reliably and with long-term stability within the specification for 15 years.

Sensor types systematically qualified for heat pump applications - demonstrable

A highly optimised design, extensive qualification programmes and semi-automated series production with maximum reproducibility reliably ensure compliance with the specification and the required 15-year service life.

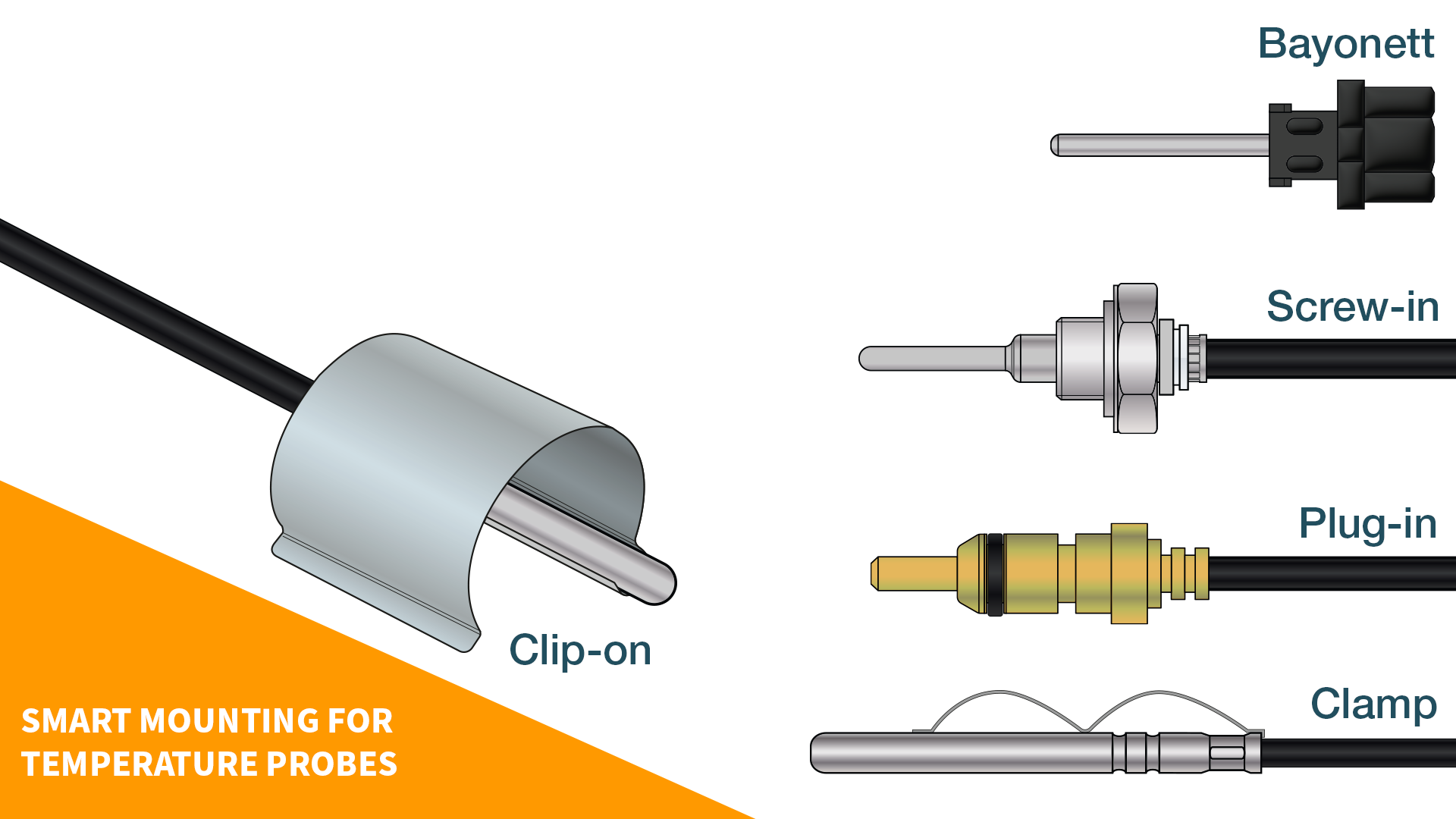

We advise you not only on your temperature probe, but also on suitable mounting systems for the application.

Our heat pump sensors undergo the following qualifications

Proof of long-term stability under temperature changes: Temperature probes are exposed to harsh environmental conditions, such as changing temperatures and high humidity, and should still function reliably in the field for 15 years or more.

Verification of long-term stability under heat and humidity: Strongly fluctuating ambient conditions mean immense stress for the temperature probe and the design must be correspondingly robust and qualified.

Proof of vibration resistance: Depending on the application, compressors and fans generate strong vibrations that are transmitted to components and cables. Therefore, the temperature probes used must be vibration-resistant (20g).

Proof of corrosion resistance (in salt spray mist): Temperature probes are also used in coastal regions. Therefore, the temperature probes must be able to withstand salty air for a lifetime of 15 years.

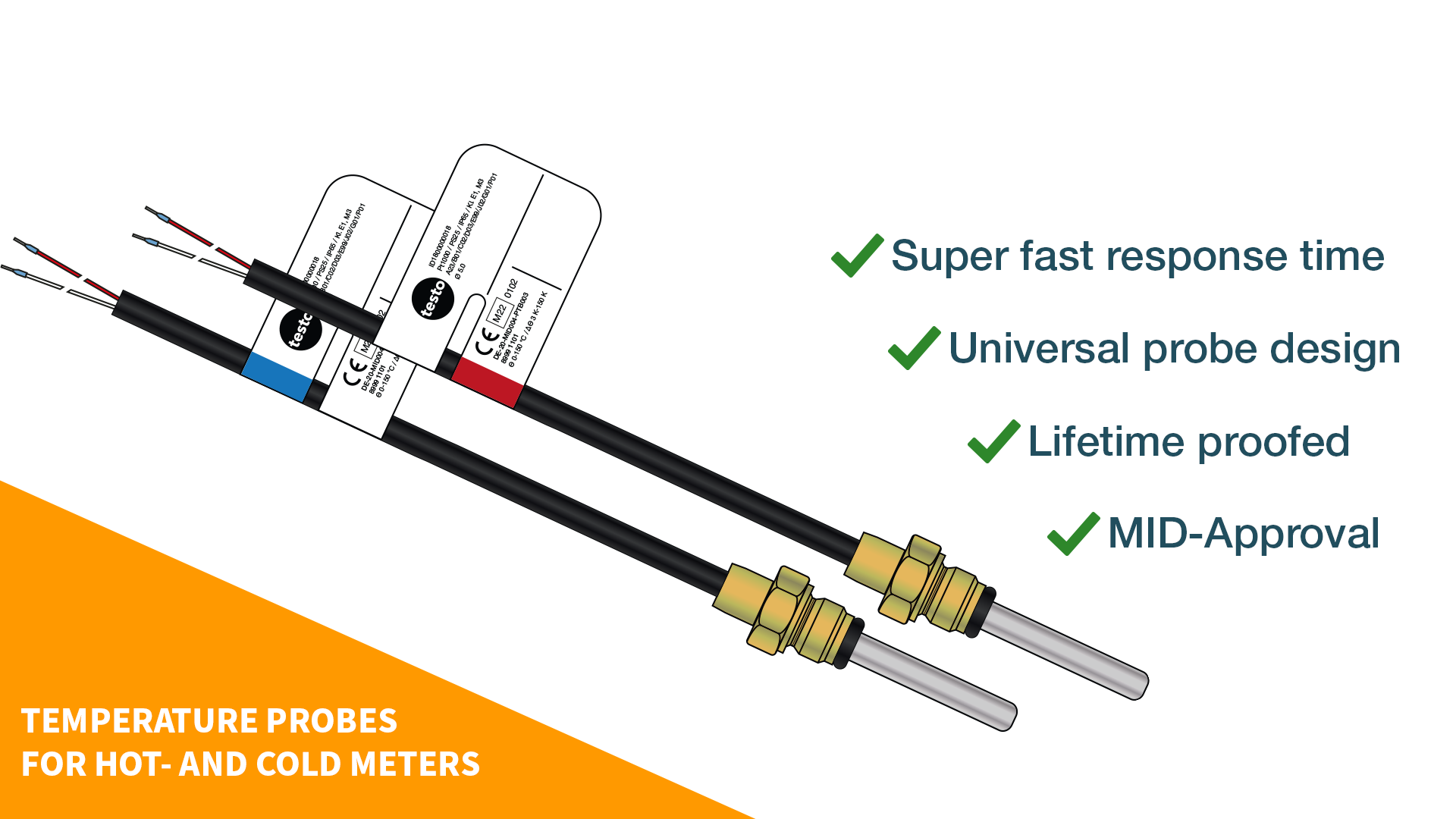

Proof of compliance with the specification (response times): Depending on the application, short response times are sometimes necessary because they ensure efficient control of the system. Our sensor design is optimised for this and we prove the response time.

Proof of compliance with the specification(pull-out force): The robust design ensures the necessary cable pull-out strength, even with vibration and higher temperatures.

Effective quality assurance in series production, consisting of 100% final inspection and additional spot checks, ensure our 0-defect quality.

Your probe could look like this:

Possible measuring elements: PT100, PT1000, PT500, PT2000, Ni500, Ni1000, Ni1000TK5000,

NTC1.8kOhm, NTC5kOhm, NTC10kOhm, NTC20kOhm

Possible circuit type (depending on measuring element): 2-wire, 3-wire, 4-wire

Protection sleeve: Diameter Ø: 3-6 mm, Length: 30- 200 mm, Sleeve shape (tip): flat or round, Material: Stainless steel 316L (copper, brass on customer request) with pressure spring or pressure bend, if necessary multiple rolled

Protection class: IP68, moisture and dew point resistant

Connection cable: Material: FEP / silicone, Color: black, other colours are possible.

Electrical connection / plug: insulated wire end sleeves, plugs possible according to specification

Suitable accessories: clamps for fixing to the pipe, heat conductive paste

Certifications and standards: Standards: DIN EN 61326-1:2013 | DIN EN 50581:2013, guidelines: RoHS 2011/65/EU, certificates: proof of suitability for heat pump applications

Discover more from us