VASEN

ELECTROFUSION HDPE FITTINGS

Explore product

MULTILAYER PERT-AL-PERT PIPES AND FITTINGS

Explore product

BUTT FUSION HDPE FITTINGS

Explore product

ELECTROFUSION HDPE FITTINGS

Explore product

MULTILAYER PERT-AL-PERT PIPES AND FITTINGS

Explore product

BUTT FUSION HDPE FITTINGS

Explore product

ELECTROFUSION HDPE FITTINGS

Explore product

MULTILAYER PERT-AL-PERT PIPES AND FITTINGS

Explore product

BUTT FUSION HDPE FITTINGS

Explore productAddress

VASEN

Avgda. Mas Vila, Num. 130-132

17457 Riudellots de La Selva

Spain

Telephone+34 972 59 68 55

Fax+34 972 59 68 50

Discover more from us

Follow us on

About us

Since its inception in 1999, VASEN specializes in R&D, manufacturing and sales of high-quality plastic pipes.

We are a leading PPR pipe manufacturer with high-tech research centers: thanks to this, we take the Lead in approving the ISO9001 quality system and the ISO14001 environmental management system, and obtaining international approvals from DVGW, AENOR, WRAS, TUV, CE, NSF, etc.

VASEN, now present in Europe, has a large team of professionals who will demonstrate effectiveness in each activity and a wide range of products that they hope to receive quickly, completely and reliably.

Our activity is focused on 3 product lines: HDPE fittings, Multilayer PERT-AL-PERT pipes and fittings and PPR pipes and fittings.

In recent years, VASEN has deepened the “intelligence” transformation and technological innovation, and insisted on providing high-end products for users. This year, VASEN continued to enhance the level of intellectual development, promote the development and production of new systems and new products, and continuously improve product competitiveness.

VASEN, now present in Europe, has a large team of professionals who will demonstrate effectiveness in each activity and a wide range of products that they hope to receive quickly, completely and reliably.

Among others, two of the most important projects in which VASEN has achieved are:

- The Hong Kong-Zhuhai-Maccao Bridge Mega Project, it is like a Chinese dragon, flying above the blue sea.Currently, it is the longest sea-crossing bridge in the world, with the world's longest submarine immersed tunnel. In 2015, the British “Guardian” selected “The Seven Wonders of the Modern World” from the buildings that are about to be completed in the world.

- The Beijing Daxing International Airport, it is ranked at the top of the "Seven Wonders of the New World" by the British media, it has achieved a number of world-class, representing the high standards of civil aviation construction in China.

VASEN has the quality certificates to carry out any type of installation with the security of working with a leading company company in your sector. We are endorsed by more than 20 years of development with more than 120 international accreditations.

Our product groups

Our application areas / Solutions

Downloads

Documents

Keywords

- electrofusion and butt fusion fittings

- pipe

- PE

- VASEN

- PPR

Our Products

ELECTROFUSION HDPE FITTINGS

HDPE base resins are manufactured in a low-pressure process, resulting in a chain structure with small side branches and a material density range of 0,930-0,960 g/cm3. HDPE materials qualify as PE80 and PE100 in accordance with ISO 4427.

HDPE materials are widely used in both pressure and non pressure applications such as water supply, drains, outfalls, and sewers in pipe sizes up to 1000 mm diameter. The increased stiffness of HDPE is used to advantage in such applications as electrical and communications conduits,

drainage, sewer and storm water.

ADVANTAGES:

- Lightweight. The density of PE materials is only 0,93-0,96 g/cm3. The weight of PE pipe is much less than that of concrete, cast iron, or steel pipe. The PE piping system is easy to handle and install, and reduced manpower and equipment requirements may result in installation savings.

- Flexibility. In some instances, the pipe's flexibility may remarkably eliminate the usage of fittings and greatly reduce installation costs. HDPE pipe can be bent to a minimum radius between 20 to 40 times the diameter of pipe, which mainly depends on the SDR of the certain pipe.

- Chemical and corrosion resistance. VASEN HDPE fittings and pipe have an excellent corrosion resistance against the majority of chemical substances in systems of potable water, irrigation, sanitary and drains. The PEAD is anti-corrosive and it is not oxidized long time.

- Odorless and insipid.

- Electrical insulating. The PEAD is an electrical conductive and it is not damaged, oxidized or corroded due to the electrolytic action.

- Thermal insulating.

- Low friction coefficient.

- Abrasion resistance. The high resistance to abrasion, flexibility, light weight, and robustness of HDPE VASEN fittings and pipes, has led to their wide usage in applications such as transportation of slurries and mine tailings.

- Ease of installation and union. Electrofusion and butt fusion.

- Recyclable.

- Long expectancy life. When the temperature is 20°C, the expectancy life is 50 years.

MULTILAYER PERT-AL-PERT PIPES AND FITTINGS

Our PERT-ALT-PERT multilayer pipes and accessories are manufactured according to ISO AENOR 21003 and UNE-EN-12165 standards and manufactured in CW617N brass.

The multilayer pipe is composed of 5 layers that make up an inner and outer layer of PERT, a central layer of aluminum, joined together by two layers of adhesive. The aluminum layer is welded to lap to give a complete oxygen barrier.

PERT-AL-PERT pipe undergoes less expansion due to increased temperatures thanks to its aluminum core.

Press-fitting technology and multilayer pipe were seen as the way to proceed. Offering more than 50% speed in installation time and 30% less accessories required when compared to other conventional systems.

With the increasing demand for high quality multilayer pipe and pressure fittings, VASEN introduces the press-fitting system. A full range of multilayer pipe and pressure fittings. This system is available in high quality brass: CW617N.

It can be used in installations with:

- MULTILAYER PRESS FITTINGS.

- MULTILAYER COMPRESSION FITTINGS.

ADVANTAGES:

Quick and safe installation.

• Easy pipe installation, simply bend and tighten, therefore

fewer accessories.

• No welding or threading.

• No copper, no theft.

• Free of corrosion.

• No guesswork, the press tool will know the degree of tension.

• High pressure and temperature resistance.

• Resistance to stress cracking and fracturing, as well as

impact shock.

• Effective response to water hammer that may occur.

• Light weight, which makes it easy to install and transport.

• Easy bending without loss of rigidity.

• Can be used with all types of water.

• Smooth interior surface, thus avoiding scale build-up.

• Resistant to corrosion.

• Very low thermal expansion; much lower than in plastic pipes.

• Minimum expansion length.

• Resistant to pressure and temperature.

• They do not alter the taste or smell of the water.

• They do not conduct electricity.

• Excellent acoustic insulation.

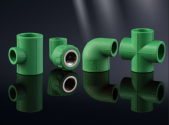

Socket Fusion polypropylene fittings: coupler, elbow 90º, elbow 45º, reducer, equal tee, reduced tee, tee cross, elbow 90º F/M, cap, plug with thread, sadle and stub end, valves, transitions, threaded fittings.

PP-R is short for polypropylene random copolymer, also named as polypropylene type 3.

ADVANTAGES:

- Light weight. The density of the pipes is only 0.89-0.91 g/cm3, which is only 1/9 of steel pipe and 1/10 of copper pipe. It makes handling and installation more convenient.

- Good heat and pressure resistance. The Vicat softening point reaches 131.3°C. Its short-term operating temperature can up to 95°C. And under thetemperature of 80°C, it still can bear some pressure for a long term. That's the best choice for cold and hot water supply pipeline in buildings.

- Long service life. Under proper temperature (70°C) and pressure (10 kg/cm2), its service life can reach 50 years.

- Good corrosion resistance. Vasen PP-R pipes have excellent corrosion resistance to most inorganic ion and common chemical substances in buildings.It is anti-corrosion and does not rust in long termuse.

- Reliable and convenient connection. PP-R material has excellent melting welding performance. The pipes and fittings are made from the same material, joined together by melting welding. Compared to single pipe, the tensile vending and impact strength in joint are much higher, which prevents the danger of leakage, and this kind of connection method also makes the site installation reliable and convenient.

- Nonpoisonous and harmless. PP-R belongs to polyolefin, which is a kind of thermoplastics, whose molecule is only composed of carbon and hydrogen.

- Good thermal and sound insulation property. The thermal conductivity coefficient of PP-R is 0.23 w/m °C, which is only 1/200 of steel pipe (43-52 w/m °C). No need to use insulating materials when used in hot water systems, which saves insulation materials and energy. And it has lower noise when delivery in pipeline system.

- Better water passing capacity. The smooth inner surface of PP-R pipes and fittings have lower friction, which ensure fast running of the water.

- Environment-friendly building material. During production, installation and application, no pollution will be caused to the environment. Meanwhile, the materials are recyclable, which can minimize resource wasting.

The PP-R accessories are used for potable water pipe networks, industrial networks for food products, chemicals and the electrical industry, for purified water and mineral water, air conditioning equipment, heating systems, rainwater harvesting systems, installations of swimming pools, networks for agriculture and horticulture and for solar energy installations.

- Copolymer random PP-R.

- Trademark: VASEN

- Certification: AENOR and DVGW.

BUTT FUSION HDPE FITTINGS

Polymers that consist only of carbon and hydrogen are called polyolefins. Polyethylene (PE) belongs to this group. It is a semi-crystalline thermoplastic. Polyethylene is the best known standard polymer. The chemical formula is (CH2-CH2) n. It is an environmentally friendly hydrocarbon.

ADVANTAGES:

- Light weight.The density of the pipe and fittings is only 0.93-0.96 g / cm3. The weight of HDPE pipe is much less than that of concrete, iron or steel. HDPE piping systems are easy to handle and install and the reduction in labor and equipment requirements can result in installation savings.

- Chemically inert and good resistance to corrosion.HDPE VASEN pipes and fittings have excellent corrosion resistance against most chemicals in drinking water, irrigation, sanitation and drainage systems. HDPE is anticorrosive and does not rust in the long term.

- Electrical insulator.HDPE is an electrical conductor and does not deteriorate, rust or corrode by electrolytic action.

- Good thermal insulator.

- Low coefficient of friction.

- Abrasion resistance.The high abrasion resistance, flexibility, light weight and robustness of HDPE VASEN pipes and fittings has led to its wide use in applications such as transportation of mining waste.

- Ease of installation and union.By electrofusion or butt welding.

- Recyclable.

- Long useful life.When the working temperature is 20 ° C, its useful life is 50 years.

Polypropylene electrofusion fittings: coupler, reducer, elbow 90º, elbow 45º, and equal tee.

ADVANTAGES:

- Light weight. The density of the pipes is only 0.89-0.91 g/cm3, which is only 1/9 of steel pipe and 1/10 of copper pipe. It makes handling and installation more convenient.

- Good heat and pressure resistance. The Vicat softening point reaches 131.3°C. Its short-term operating temperature can up to 95°C. And under thetemperature of 80°C, it still can bear some pressure for a long term. That's the best choice for cold and hot water supply pipeline in buildings.

- Long service life. Under proper temperature (70°C) and pressure (10 kg/cm2), its service life can reach 50 years.

- Good corrosion resistance. Vasen PP-R pipes have excellent corrosion resistance to most inorganic ion and common chemical substances in buildings.It is anti-corrosion and does not rust in long termuse.

- Reliable and convenient connection. PP-R material has excellent melting welding performance. The pipes and fittings are made from the same material, joined together by melting welding. Compared to single pipe, the tensile vending and impact strength in joint are much higher, which prevents the danger of leakage, and this kind of connection method also makes the site installation reliable and convenient.

- Nonpoisonous and harmless. PP-R belongs to polyolefin, which is a kind of thermoplastics, whose molecule is only composed of carbon and hydrogen.

- Good thermal and sound insulation property. The thermal conductivity coefficient of PP-R is 0.23 w/m °C, which is only 1/200 of steel pipe (43-52 w/m °C). No need to use insulating materials when used in hot water systems, which saves insulation materials and energy. And it has lower noise when delivery in pipeline system.

- Better water passing capacity. The smooth inner surface of PP-R pipes and fittings have lower friction, which ensure fast running of the water.

- Environment-friendly building material. During production, installation and application, no pollution will be caused to the environment. Meanwhile, the materials are recyclable, which can minimize resource wasting.

The PP-R accessories are used for potable water pipe networks, industrial networks for food products, chemicals and the electrical industry, for purified water and mineral water, air conditioning equipment, heating systems, rainwater harvesting systems, installations of swimming pools, networks for agriculture and horticulture and for solar energy installations.

- Copolymer random PP-R.

- Trademark: VASEN

- Certification: AENOR.