Rotek Enerji ve Baca Sistemleri Sanayi ve Ticaret Ltd. Sti.

Address

Rotek Enerji ve Baca Sistemleri Sanayi ve Ticaret Ltd. Sti.

Cerkesli OSB Mah. Imes 9. Cad. Dilovasi

No: 27 41455 Kocaeli

Türkiye

Telephone+90 262 502 46 66

Discover more from us

About us

Since Rotek was founded in 1993, Rotek has been supplying wide solutions about chimney system for purchasers. Company founders gained experience in Turkey area by trading and installing products of various German Chimney Companies. In 1993, The Company began to production of stainless steel chimney systems with Rotek trademark. Since entering to the chimney sector, Rotek with its acquirements and experiences became a pioneer of relevant with standards and conscious utilization of chimney systems and has been serving until now with this respect. Rotek is the first company approved for CE Certification according to European Harmony Standards in Turkey. Rotek has most wide capacity with respect to machine and mold between Chimney companies in Turkey. In totally 20 Countries in Europe, Asia and Africa Continents, Rotek exporting hundreds of chimney systems, filter systems, linen and refuse chutes became a trademark of in demand with its quality in project specifications. The first circumstance for exporting to Turk Republics and Russia trade area, Gost-r Quality Certificate, was taken firstly by Rotek in Turkey in 2006. Formerly “conic fitting” systems and “manual welding” were used, by the following up innovations in chimney sectors for the purpose of producing better quality products Rotek changed the applications and started to use “robot welding” technology by 1996, “enlargement” system by 1999 and “readymade gasket system” by 2007. As well as stainless steel chimney systems, with refuse chute, linen chute, self standing chimney systems, filter systems contents of products, it is in the previously preferred companies by buildings, business center, hotels, hospitals and industrial complexes. Rotek is the first company in Turkey producing acceptable linen and refuse chutes according to the international standards. In Turkey the first company that set up distributor net, Rotek has 26 distributors in various cities in Turkey and target to establish distributors in all cities in Turkey. Rotek is the rare company in the world with supplying manufacturing, sales and montage of goods and also solving chimney problems, design of chimney systems, selection of chimney equipments (fan, chimney damper, motorized damper, silencer and so on) and services after sales. Rotek Company can recon all necessary calculations and represent technical report in case of necessity, by involving Master Degree Mechanical Engineers.

https://members.isib.org.tr/company/rotek-enerji-ve-baca-sistemleri-sanayi-ve-ticaret-ltdsti

ROTEK Chimney Systems

Products Stainless Steel Chimney Systems Free-Standing Chimney Sysytems,Linen Chutes, Trash Chutes, Kitchen Ducts-EI120 Label, Fireplace Chimneys and Fans, Draught Regulator for Chimneys, Compactor for Garbages, Self Flanged Circular Ducts , Grease and odour elimination for industrial kitchens, Separator for Garbages, Chute Doors-EI90 Label, Electrostatic Filter, Jet Fans Casing, High Efficiency Hoods System for Industrial Kitchens

Our product groups

Our application areas / Solutions

Downloads

Documents

Keywords

- Stainless Steel Chimney

- Edelstahlschornsteine

- Linen and Garbage Chutes

- Free standing chimneys

- Marine SOX Scrubbers

- Fire Resistant Duct

- Self Flanged Chimney System

- Self Flanged Duct for fan body

- Draught Regulator

- Separator system for the waste containers

Our Products

Linen Chutes- Refuse Chutes

Linen Chutes:

Rotek linen chutes are specially designed for use in hotels and hospitals.

Since the linen chutes are directly connected to the laundry rooms, they prevent visual disturbance while carrying the laundry and save labor costs. With the ventilation chimneys connected to the Rotek linen chutes, the moisture is absorbed by natural draft.

Full safety is achieved with the warning lights and automatic lock systems on the linen doors.

The door neck section are made long enough to prevent the reach of the arm inside the linen chute and thus, accidents are avoided. The diameters of Rotek linen chutes are determined according to the height of the building and the laundry capacity either as

Ø 600 or Ø 800 mm.

The intake doors will be AISI 304 quality stainless steel. All chute sections will be welded by a robot under shielding gas (TIG). The welds were made with manual TIG will be rectified so the garbage can easily fall free without fastening upon any offsets or obstructions within the chute. All intake doors have 1 1/2 hour fire resistance(EI90 Fire Resistance Test Certificate- EN 1634-1:2014). All chute sections will be assembled through “male-female” joints, on suitably calibrated and self–centering. Modules that will be manufactured with cone-shaped shall not be used in the chute system.

Refuse Chutes:

Rotek refuse chutes provide ease of use with their special diameter designs and hooper designs realized in accordance with the fields of use. The harmful matters contained in the garbage are eliminated by spraying chemicals.This way, they prevent bad odors and flies and have an important role in environmental health; in addition, they put an end to visual pollution, thanks to the closed system. Fresh air is circulated continuously in order to prevent harmful gases and bad odors leaking into the rooms from the hoopers with the ventilation fans used in Rotek refuse

chutes. Full safety is achieved with the warning lights on the hoopers.

Noise insulation is employed for avoiding disturbance to the environment during operation.

Rotek refuse chutes are specially designed for use in hotels, hospitals, residences, commercial buildings, factories, etc. If it is not possible to place the chute inside the building due to structural reasons, or to replace old, unhealthy or unfunctional chutes, the system is installed outside the building.

The diameters of the Rotek refuse chutes are determined in accordance with the height of the building, field of use and the type of garbage among diameters of

Ø 450, Ø 500, Ø 550, Ø 600 or Ø 800 mm.

The intake doors will be AISI 304 quality stainless steel. All chute sections will be welded by a robot under shielding gas (TIG). The welds were made with manual TIG will be rectified so the garbage can easily fall free without fastening upon any offsets or obstructions within the chute. All intake doors have 1 1/2 hour fire resistance(EI90 Fire Resistance Test Certificate- EN 1634-1:2014). All chute sections will be assembled through “male-female” joints, on suitably calibrated and self–centering. Modules that will be manufactured with cone-shaped shall not be used in the chute system.

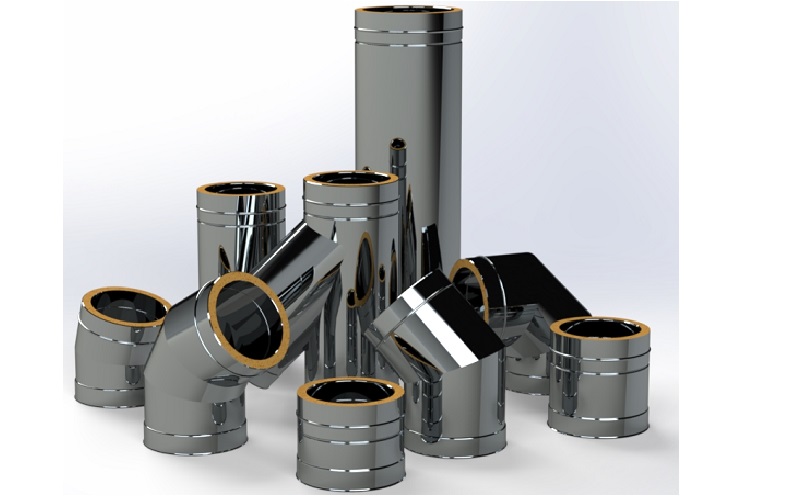

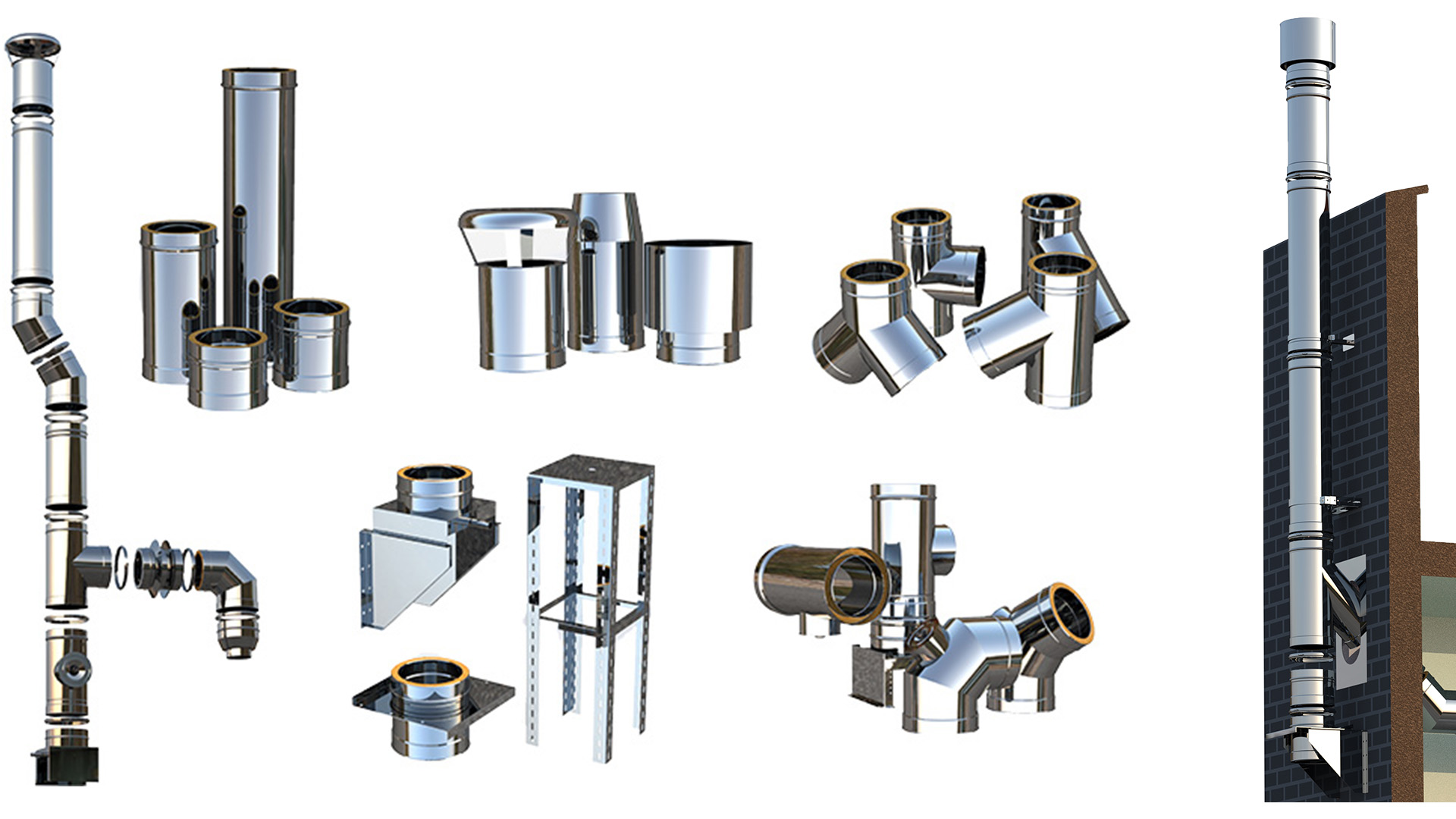

RTKMono D Series-Double Wall Stainless Steel Chimney System

Type

Double Wall Stainless Steel Chimney System

CE Classifications - EN1856-1

(W) Systems:

T600-N1 -W-V2-L50(040-300)-060 (DN80-300)

T600-N1 -W-V2-L50(050-300)-090 (DN301 -450)

T600-N1 -W-V2-L50(050-300)-0120 (DN451-500)

T600-N1 -W-V2-L50(060-300)-0120 (DN501-600)

T600-N1 -W-V2-L50(080-300)-0240 (DN601-800)

T600-N1 -W-V2-L50(090-300)-0240 (DN801-1000)

T600-N1 -W-V2-L50(100-300)-0240 (DN1001 -1200)

(D) Systems:

T600-N1 -D-V2-L50(040-300)-G60 (DN80-300)

T600-N1 -D-V2-L50(050-300)-G90 (DN301 -450)

T600-N1 -D-V2-L50(050-300)-G120 (DN451-500)

T600-N1 -D-V2-L50(060-300)-G120 (DN501-600)

T600-N1 -D-V2-L50(080-300)-G240 (DN601-800)

T600-N1 -D-V2-L50(090-300)-G240 (DN801-1000)

T600-N1 -D-V2-L50(100-300)-G240 (DN1001 -1200)

Working Temperature

600 °C

Corrosion Class

V2

Pressure Class

N1 (Negative Pressure 40Pa)

Usage of Application

Wet (W) and Dry (D) systems

Material

Inner wall

Stainless Steel (316L / 1.4404)

Outer wall

Stainless Steel (304 / 1.4301)

Insulation

30-50mm Mineral wool

Welding Seam

TIG/PLASMA continuous

Connection Form

Male-female connection with clip

Seal Material

Heat resistance silicone

Unintentionally Contact

Must be under the protection

Freeze Thaw Resistance

Yes

Soot Fire Resistance

Yes

Average Roughness

1mm

Self Flanged Chimney System

RTKFL – Series RTKFL self-flange flue system is a Rotek patented productdesigned for industrial use. This self-flange product is produced as welded onautomatic benches without human touch, and then bolt holes of the desireddiameter and number can be drilled on the flange. Since the system is selfflanged, it is rigid, durable, compact and decorative. Due to the highstrength, there is no need for short distance fixation in horizontal transportof gases. Gas tightness can be achieved at high pressures by using a specialgasket between two flanges according to the characteristics of the gas passingthrough it. This product is also used as a fan body. It can be produced indesired diameters and thicknesses.

Test certificate :

Insulated stainless steel circular ventilation duct ,

Fire resistance : EI 120 (ve, i-》o)

Fire resistance : EI 180 (ve, i-》o)

Scope of application

- Air transport systems;

- Industrial and kitchen hood discharge duct systems,

- Factory process channels in sectors such as food, medicine, etc.,

- Filter connection channels in treatment plants

- As a fan body,

- In the transport of process gases with a gas temperature of 1100°C

Double Wall Free Standing Chimneys ( Singleflue or multiflue) - RTK-FS4

RTK-FS self standing chimney systems are usually used in industrial plantsor factories, power plants, waste water or gas treatment plants,petrochemical complex and in places where the boiler room is far from themain building. The chimney is double walled, foundation anchored andstand alone type. The inner walls may be manufactured with continouswelded or flange connected and available to H0 tightness class accordingto the type of use. Rockwool or ceramic wool insulation is insertedbetween the walls. It has low thermal conductivity, since the heat of the chimney gas is not considerably transferred to the environment, thechimney eciency is high. The outer shell are designed in accordancewith the static load conditions and made of steel. The shell may be epoxycoated or cladded with stainless steel for protection from atmosphericcorrosion. The chimneys may be designed for wet or dry systems up to 1000 °C temperature.

The CE label is affixed to certify that it is produced in compliance with the standards for chimneys produced according to EN 13084-7.

T550-H0-D-L20-1.4301-G T550-H0-D-L20-1.4541-G

T550-H0-W-L20-1.4571-G T550-H0-W-L20-1.4404-G

T550-H0-W-H20-1.4571-G T550-H0-W-H20-1.4404-G

T550-H0-W-V20-1.4539-G T750-H0-D-L20-1.4828-G

T1000-H0-D-L20-1.4841-G

RTK Series-Single Wall Stainless Steel Chimney System

Type

Single Wall Stainless Steel Chimney System

CE Classifications - EN1856-1

(W) Systems:

T400-N1 -W-V2-L50(040-300)-0250 (DN80-300)

T400-N1 -W-V2-L50(050-300)-0375 (DN301 -450)

T400-N1 -W-V2-L50(050-300)-0500 (DN451 -500)

T400-N1 -W-V2-L50(060-300)-0500 (DN501 -600)

T400-N1 -W-V2-L50(080-300)-01000 (DN601 -800)

T400-N1 -W-V2-L50(090-300)-01000 (DN801 -1000)

T400-N1 -W-V2-L50(100-300)-01000 (DN1001 -1200)

(D) Systems:

T400-N1 -D-V2-L50(040-300)-G250 (DN80-300)

T400-N1 -D-V2-L50(050-300)-G375 (DN301 -450)

T400-N1 -D-V2-L50(050-300)-G500 (DN451 -500)

T400-N1 -D-V2-L50(060-300)-G500 (DN501 -600)

T400-N1 -D-V2-L50(080-300)-G1000 (DN601 -800)

T400-N1 -D-V2-L50(090-300)-G1000 (DN801 -1000)

T400-N1 -D-V2-L50(100-300)-G1000 (DN1001 -1200)

Working Temperature

400 °C

Corrosion Class

V2

Pressure Class

N1 (Negative Pressure 40Pa)

Usage of Application

Wet (W) and Dry (D) systems

Material

Inner wall

Stainless Steel (316L / 1.4404)

Outer wall

-

Insulation

-

Welding Seam

TIG/PLASMA continuous

Connection Form

Male-female connection with clip

Seal Material

Heat resistance silicone

Unintentionally Contact

Must be under the protection

Freeze Thaw Resistance

Yes

Soot Fire Resistance

Yes

Average Roughness

1mm

Our Contact Persons

Oguz ALTIPARMAK

General management

Managing Director