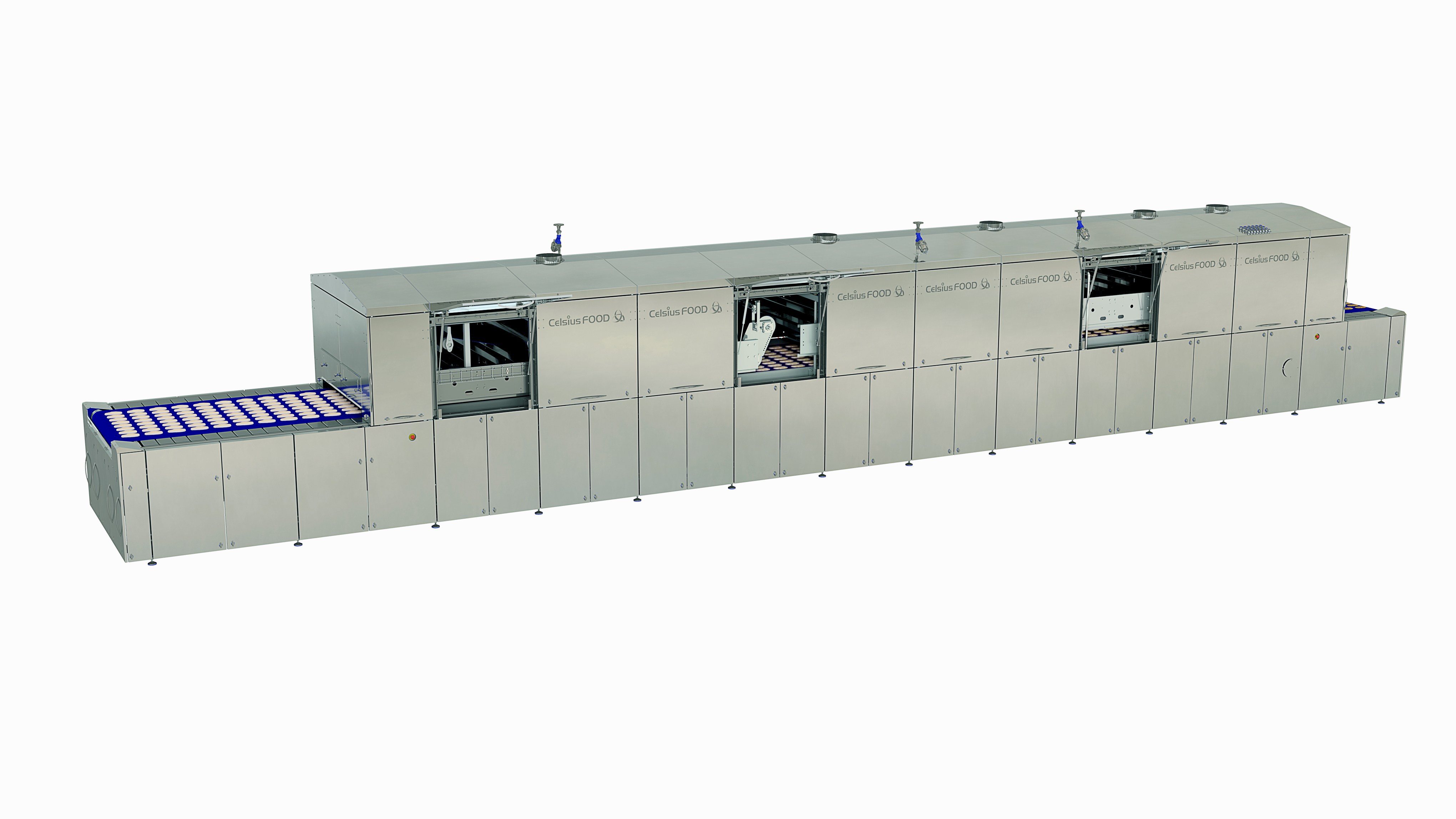

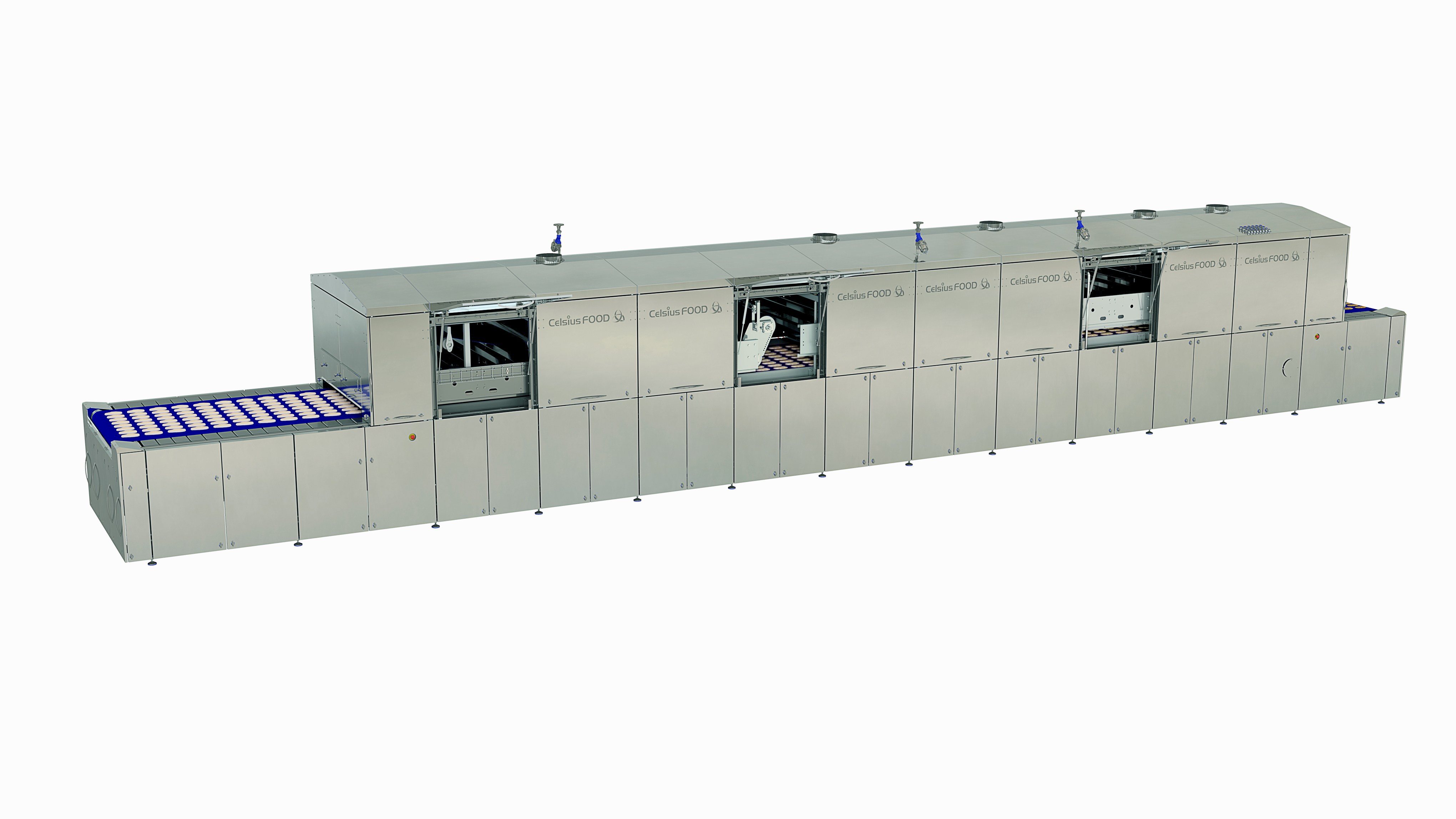

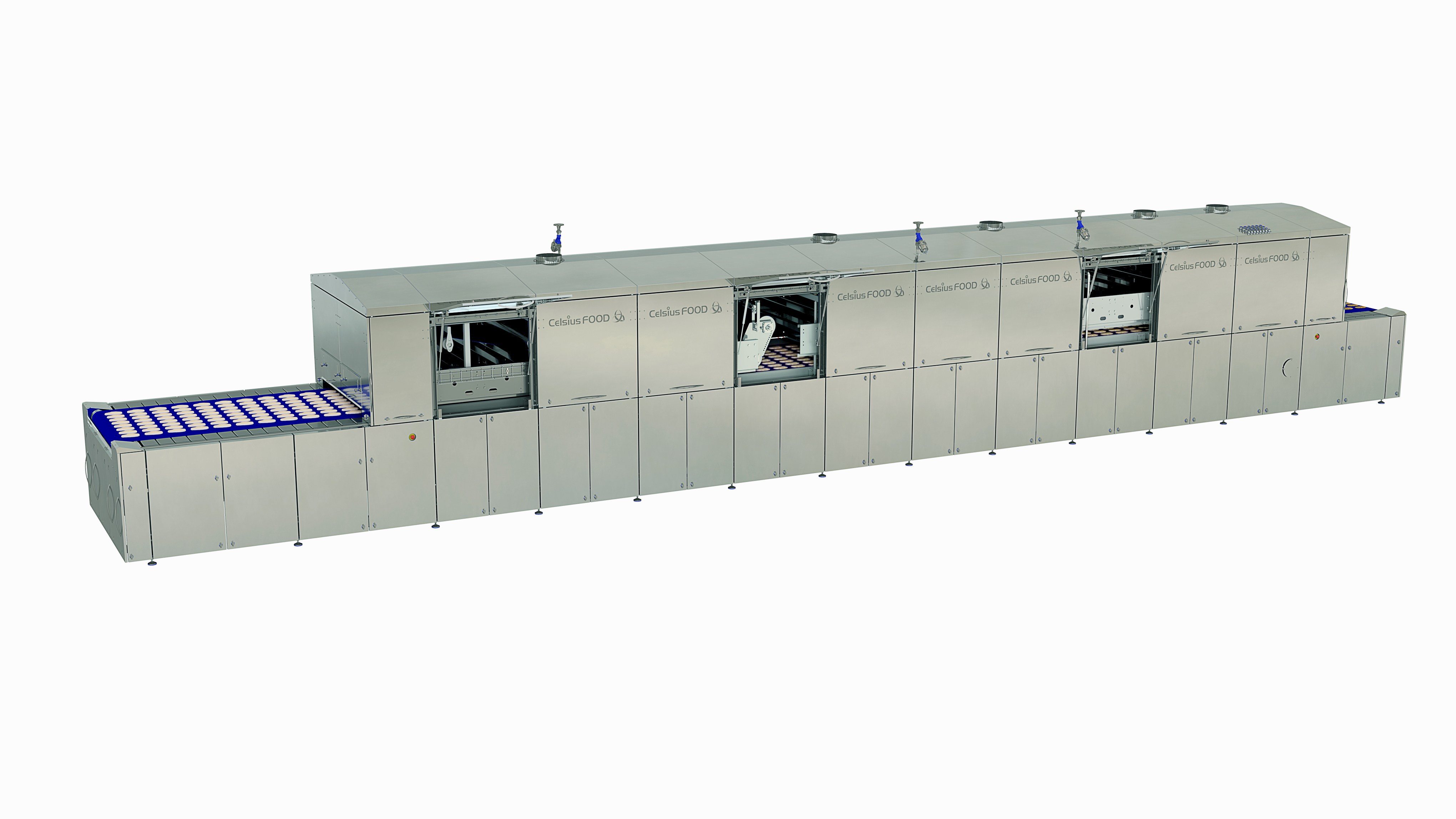

CelsiusFOOD

CelsiusFOOD Machines – All Cooking Technologies

Explore product

Twin-COOK Pilot

Explore product

CelsiusFOOD Machines – All Cooking Technologies

Explore product

Twin-COOK Pilot

Explore product

CelsiusFOOD Machines – All Cooking Technologies

Explore product

Twin-COOK Pilot

Explore productAbout us

At CelsiusFOOD, we engineer continuous ovens and cooking lines that maximize efficiency, precision, and yield for the global food industry. Our contact and combination cooking systems ensure optimal product quality, while reducing energy consumption and processing time.

With over 10 years of experience and more than 70 installations worldwide, CelsiusFOOD provides modular, high-performance cooking technology for a wide range of applications, including bacon, poultry, plant-based proteins, and ready-to-eat meals.

Our Solutions:

🔥 TWIN COOK & ECO-GRILLS – Efficient, flexible contact cooking solutions for uniform results.

🔥 Custom Cooking Systems – Tailored to your production needs, integrating:

- Contact cooking for direct heat transfer

- A combination of conduction & convection for precise control

- Pre-cooling for optimized product handling

- Modular design, allowing all cooking techniques to be assembled in one machine

🔥 DuraPlate Technology – A breakthrough modular cooking surface ensuring superior heat transfer and easy maintenance.

🔹 After the demos, our team will be available to answer your questions. If you’d like to discuss further, we invite you to schedule a private appointment for a more in-depth conversation.

📍 Meet us at IFFA 2025 – Booth 9.0 B29 and discover how CelsiusFOOD can optimize your cooking process with smarter, more efficient technology.

🔗 Visit us online: www.celsiusfood.com

More about us

Special Interests

Keywords

- Cooking systems

- Contact cooker

- Linear oven

- Cookers

- Industrial cooking equipment

Our Products

CelsiusFOOD Machines – All Cooking Technologies

CelsiusFOOD offers the most versatile range of contact and hybrid cooking systems in the food processing industry. All machines are designed for precision, yield optimization, hygiene, and seamless integration into modern industrial lines. CelsiusFOOD technologies are based on heated or cooled PTFE belts. We offer five core cooking and cooling technologies:

1. ConDuo – Double Belt Contact Cooking (Top & Bottom)

Technology: Two heated PTFE belts

Temperature range: Up to 260°C

Belt gap range: 2–190 mm, adjustable in 0.1 mm increments

ConDuo is our flagship contact cooking system. Products are transported between two heated PTFE belts, which apply controlled pressure and temperature from both sides. The belt gap can be precisely adjusted to gently touch or compress the product. This allows for excellent core temperature uniformity, while preserving product shape and texture.

The dual-belt system improves yield by preventing both undercooking and overcooking. It is especially effective for searing, surface browning, or full cooking of a wide variety of products including sliced, formed, and whole-muscle meats. Its precise thermal control makes it ideal for protein products with high quality expectations.

Applications:

Sliced meats

Reformed or marinated products

Boneless muscle cuts

Bacon, burgers, chicken filets

2. ConduVec – Hybrid Cooking (Contact + Overhead Radiant Heat)

Technology: Heated bottom PTFE belt + adjustable electric resistances above

Temperature range: Belt up to 260°C, resistances up to 800°C

Distance from resistances to product: 110–400 mm

ConduVec combines conduction and radiant heat in a compact unit. Products move on a heated PTFE belt while top-side cooking is achieved via adjustable electric resistances. When positioned close, these elements deliver intense heat for surface coloration; when positioned higher, they create a static oven-like environment for balanced cooking.

This hybrid method prevents the “hairdryer effect” — typical of forced air ovens — by avoiding moving air. As a result, it reduces dehydration, enhances yield, and maintains surface integrity.

Applications:

Meatballs, sausages

Wings and marinated chicken parts

Bone-in and boneless items

Shaped or formed products

3. ConUno – Single Belt Contact Cooking (Bottom Only)

Technology: Heated PTFE belt (bottom only)

Temperature range: Up to 260°C

ConUno is designed for bottom-side cooking and poaching applications. Products are gently heated by conduction on a single PTFE belt, which ensures clean, non-stick handling and excellent thermal transfer.

It is especially useful for preventing sticky or marinated products from adhering to steel belts or wire mesh in spiral or linear ovens. ConUno can be used as a pre-step before grilling, or as a standalone poaching solution.

Applications:

Marinated chicken filets

Sticky or fragile products

Partial cooking for further processing

4. ConVec – Radiant Heat Oven with Metal Belt

Technology: Metal conveyor + adjustable electric resistances above

Temperature range: Up to 800°C

Distance from resistances to product: 110–400 mm

ConVec is CelsiusFOOD’s radiant oven system. Products are placed on a metal conveyor and heated from above using electric resistances. Like ConduVec, the distance between the resistances and the product can be adjusted to change the heating intensity.

The system operates with static air (no circulation), preventing excessive dehydration. ConVec is particularly suited for tray-based products and applications where surface coloration or cooking finish is needed after an initial cooking phase.

Applications:

Tray meals (lasagna, gratin)

Cook-and-hold lines

Post-cooking coloration or balancing

Final cooking in multi-step lines

5. ConCool – Surface Cooling by Contact

Technology: Dual cooled PTFE belts

Temperature range: As low as -10°C

Belt gap range: 2–190 mm, adjustable

ConCool is CelsiusFOOD’s solution for post-cooking surface cooling. Using two chilled PTFE belts, it rapidly lowers the surface temperature of products after cooking to below 38°C. This cooling method helps retain moisture, reduce evaporation, and improve slicing or packaging consistency.

By reducing surface temperature quickly, ConCool minimizes juice loss during storage or freezing — especially critical for fully cooked chicken filets or meat patties.

Applications:

Cooked chicken filets and portions

Chopped meat products

Sliced proteins for sandwich applications

Lines requiring fast temperature drop before packing or slicing

Why Choose CelsiusFOOD Technologies?

Precision cooking: Adjustable parameters ensure ideal temperature and product thickness every time.

PTFE belts: Non-stick, hygienic, and compatible with aggressive cleaning.

Energy efficiency: Direct heat transfer via conduction and radiant elements reduces energy consumption.

Modularity: All systems are designed to be modular, scalable, and easy to integrate.

Yield optimization: Less dehydration, fewer losses, better flavor and appearance.

Easy maintenance: Systems are designed for rapid access and fast cleaning.

Twin-COOK Pilot

The Twin-COOK Pilot is a compact tabletop Contact Cooker designed specifically for R&D laboratories, test kitchens, and market validation projects. It uses CelsiusFOOD’s proven double contact cooking technology to replicate industrial results on a small scale—ideal for teams developing new recipes, testing cooking parameters, or preparing pre-launch samples.

Real Cooking, Small Format

The Twin-COOK Pilot applies controlled heat to both sides of the product simultaneously, using non-stick belts for gentle handling and excellent thermal transfer. Despite its small size, it delivers real process performance and reproducible results.

With a throughput of up to 90 kg/h of burger patties, it’s perfectly suited for:

Product development and prototyping

Pre-launch or market sample preparation

Internal cooking tests and quality validation

Comparative trials for clients or internal teams

Plug & Play Simplicity

This machine is ready to use straight out of the box—no installation, no utilities beyond a standard 16A plug. Its user-friendly interface lets operators adjust cooking parameters (belt speed, temperature, contact time) using a simple control panel, with minimal training.

Why Choose the Twin-COOK Pilot?

Tabletop format, easy to move and operate

Quick setup for flexible R&D or sample production

Same cooking principle as full-size CelsiusFOOD Contact Cookers

Ideal for pilot-scale trials without the need for industrial infrastructure

Affordable solution for innovation labs, marketing teams, and small-scale production runs

Whether you're developing the next big product in your lineup or preparing customer samples for a sales pitch, the Twin-COOK Pilot gives you the tools to create, test, and validate—without the complexity of a full production line.

EcoGRILL – Contact Cooker with ConDuo Technology

EcoGRILL is CelsiusFOOD’s most accessible Contact Cooker, designed for food producers looking for an affordable and efficient solution to cook, sear, or brown products using ConDuo double-belt contact technology. Ideal for non-intensive production environments, EcoGRILL offers consistent cooking results while keeping things simple—easy to operate, easy to clean, and easy to integrate.

Technology: ConDuo (Double-Sided Contact Cooking)

EcoGRILL uses two heated PTFE belts to apply heat from the top and bottom of the product at the same time. The distance between the belts is adjustable from 2 mm to 190 mm, in 0.1 mm steps, allowing the user to lightly press the product or apply more contact, depending on the recipe.

Max temperature: 260°C

Adjustable belt gap: 2–190 mm

This method ensures even cooking and gentle handling, especially useful for delicate or sticky products that could otherwise stick to metal surfaces.

What Makes EcoGRILL Different?

Cost-effective Contact Cooker for non-intensive production

Easy to set up, clean, and maintain

Suitable for both testing and small-to-medium production runs

Built with non-stick PTFE belts – perfect for marinated, soft, or thin products

Can be used as a first step in a line or standalone

Applications

EcoGRILL is suited for food companies who want to improve product quality without over-investing in high-capacity equipment. It delivers excellent results on:

Chicken filets and thin meat cuts

Burgers and plant-based patties

Reformed meats, including lightly cooked ham or bacon

Pre-cooked products requiring surface coloring

Test kitchen use for process development or pilot batches

An Easy Way to Start with Contact Cooking

EcoGRILL is a practical first step into the world of industrial Contact Cookers. It allows you to benefit from the same core technology used in high-end systems—ConDuo double-sided cooking—but in a simpler, more affordable format. With precise temperature and belt control, it ensures even cooking and high product yield, all while being easy to clean and operate.

Whether you’re cooking, searing, or just looking for surface color, EcoGRILL delivers reliable results at a lower investment, with all the key features that make CelsiusFOOD’s contact cooking systems so effective.

Twin-COOK 4.1, 4.2, and 6.2 – Double Contact Cookers

The Twin-COOK 4.1, 4.2, and 6.2 are simple, efficient Contact Cookers designed for semi-industrial production needs. These machines offer consistent cooking results using top and bottom heat to cook, sear, or color food products—all in one step.

Built for food producers who need reliability and ease of use without investing in complex, high-capacity lines, Twin-COOK systems are ideal for both meat and plant-based applications.

Ready to Run – No Complexity

Twin-COOK machines are delivered fully assembled and ready to operate. There’s no need for integration, special installation, or engineering. Just connect the machine, set your recipe, and run production.

They are easy to clean, simple to operate, and built for consistent results batch after batch.

Three Versions – Same Purpose

Twin-COOK 4.1: A practical option for simple cooking tasks and moderate volumes

Twin-COOK 4.2: Double the length compare to a 4.1!

Twin-COOK 6.2: A wider machine to handle larger batches or more product per run

Each version uses the same core technology—direct contact cooking from top and bottom—and is suited for teams looking to deliver high-quality products without investing in full industrial systems.

What Can You Cook with Twin-COOK?

Chicken filets

Burgers and plant-based patties

Bacon and ham

Pre-cooked or reformed products

Products needing surface coloration or internal cooking

Smart Choice for Mid-Level Production

If you're looking for a no-fuss, affordable cooking solution that gives you high-quality results, Twin-COOK machines are a smart choice. They allow small and medium-sized food companies to step into controlled, double-sided cooking without the need for automation, integration, or oversized equipment.

Our Events

Perfectly Cooked Chicken – In Less Than 5 Minutes!

Discover how to cook chicken parts—breasts, inner fillets, cubes, and more—in under 5 minutes using our advanced cooking technology. Experience perfect doneness, juiciness, and uniform browning, all while maximizing efficiency and yield.

Perfectly Cooked Chicken – In Less Than 5 Minutes!

Discover how to cook chicken parts—breasts, inner fillets, cubes, and more—in under 5 minutes using our advanced cooking technology. Experience perfect doneness, juiciness, and uniform browning, all while maximizing efficiency and yield.

Perfectly Cooked Chicken – In Less Than 5 Minutes!

Discover how to cook chicken parts—breasts, inner fillets, cubes, and more—in under 5 minutes using our advanced cooking technology. Experience perfect doneness, juiciness, and uniform browning, all while maximizing efficiency and yield.

Perfectly Cooked Chicken – In Less Than 5 Minutes!

Discover how to cook chicken parts—breasts, inner fillets, cubes, and more—in under 5 minutes using our advanced cooking technology. Experience perfect doneness, juiciness, and uniform browning, all while maximizing efficiency and yield.

Perfectly Cooked Chicken – In Less Than 5 Minutes!

Discover how to cook chicken parts—breasts, inner fillets, cubes, and more—in under 5 minutes using our advanced cooking technology. Experience perfect doneness, juiciness, and uniform browning, all while maximizing efficiency and yield.