How air quality affects materials and processes in production facilities.

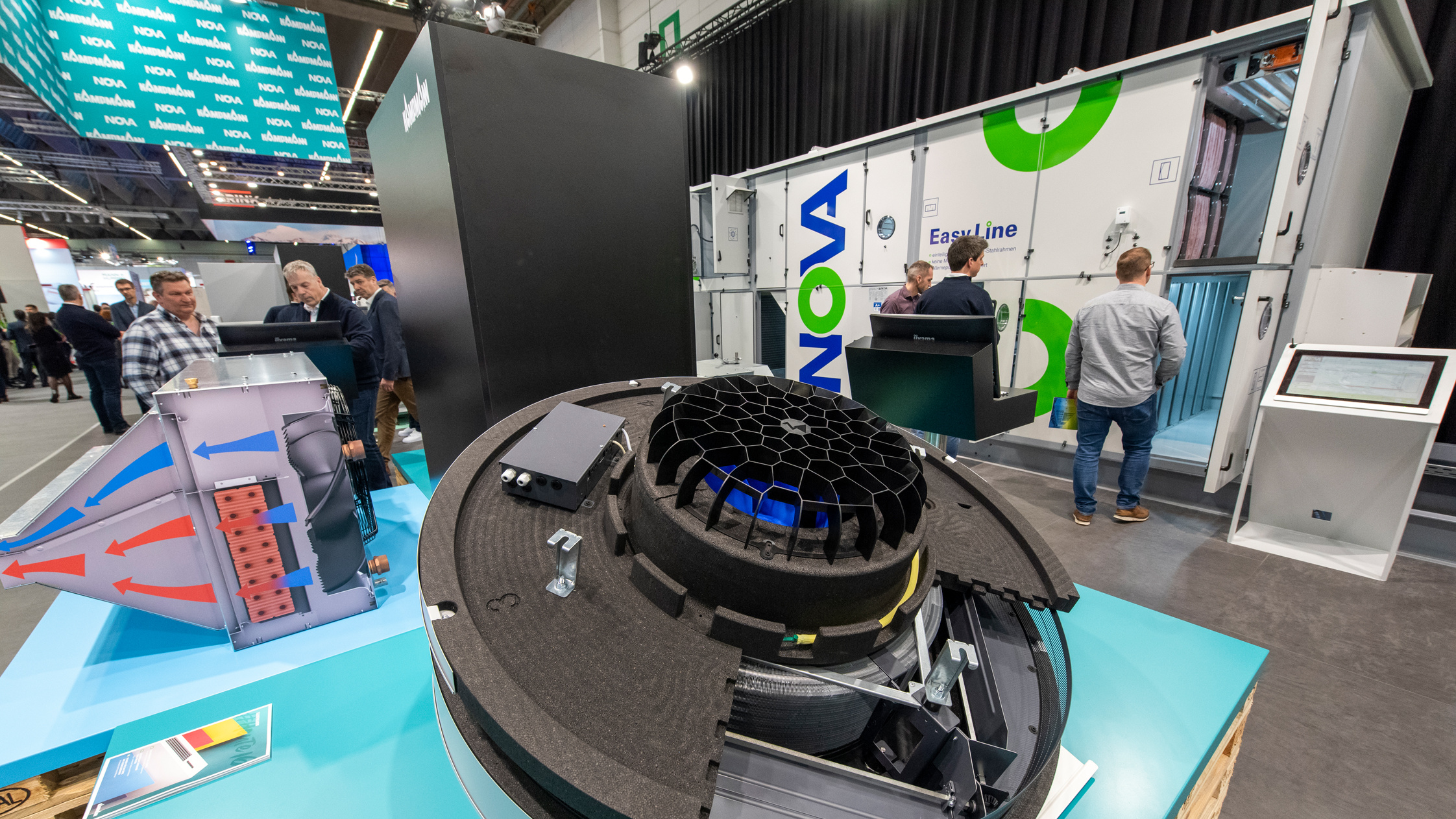

The quality of the air in industrial-process buildings affects not only the productivity and well-being of employees but also the efficiency and quality of the manufacturing processes. The use of modern ve ntilation solutions and HVAC systems (heating, ventilation and air conditioning) creates the optimum conditions for production of all kinds. As the world's leading trade fair for the sector, ISH offers insights into the latest developments in the field of ventilation and air-conditioning technology for production facilities.

Efficient ventilation for industrial plants

Industrial plants require solutions that not only ensure good air quality but also use energy efficiently. Modern HVAC systems for industrial-process buildings are designed to regulate both temperature and humidity to ensure an optimum indoor climate at all times. Deviations from this can have a negative impact on material properties and production processes. However, an optimum indoor climate is important not only for materials and machines. When considering ventilation systems, the focus should be on the people who work there. In other words, the air in production halls must provide a healthy working environment for employees at the same time as meeting the requirements of the manufacturing processes.

The significance of humidity and temperature

The significance of humidity is often underestimated in production plants. Dry air can lead to changes in the materials being processed and to electrostatic build-up, which in turn can disrupt production and generate additional costs. Materials that absorb water, such as paper, cardboard or wood, are particularly affected by humidity. Thus, maintaining a constant humidity level tailored to the individual production processes ensures high-quality end products and guarantees trouble-free production.

Like humidity, temperature is also a critical process parameter. Waste heat from machines can lead to high thermal loads, which not only increase the cooling requirements and thus operating costs but also have a negative impact on product quality. Careful temperature monitoring is therefore necessary to avoid unwanted effects on materials and to ensure that production processes run as smoothly as possible.

A pleasant interior climate has an immediate impact on the health and productive capacity of employees. Studies show that optimum temperature and humidity levels result in less absenteeism and higher product quality. A healthy interior climate also raises employee satisfaction and their sense of well-being when at work.

Future-oriented solutions at ISH 2025

ISH is the perfect opportunity to find out about the latest industrial ventilation systems and solutions to specific problems in industrial-process buildings. From air-conditioning in production facilities to improving the quality of air in production plants to energy-efficient ventilation systems, visitors can be sure of finding tailor-made solutions for all branches of industry.