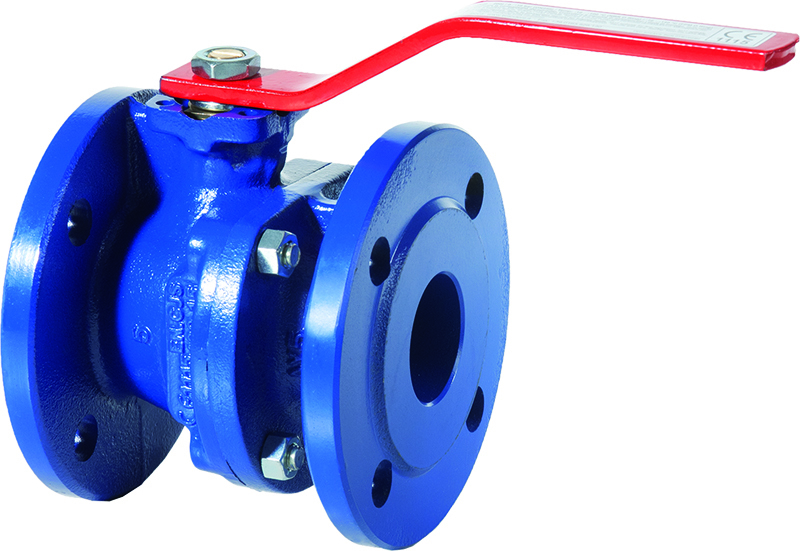

Serie ECO3F Flanged back flow preventer with controllable reduced pressure zone

Serie ECO3F Flanged back flow preventer with controllable reduced pressure zone

Description

The ECO 3F flanged backflow preventers, which have a controllable reduced pressure zone, type BA EN1717, are approved in conformity with EN12729 and are manufactured in accordance with the most severe product norms and in conformity with the quality requirements of EN ISO 9001.

They consist of 2 spring check valves and a chamber situated between the spring check valves that contain a security valve, which in the event of “backflow”, isolates the primary network from the user network. The backflow might be caused by siphoning (the entry pressure decreases due to ruptures in the piping upstream, the water supply is interrupted, partially draining parts of the piping, as a result of the events upstream) or by increasing counter pressure (the pressure of the user network is higher than the pressure in the primary network due to overpressure caused, for example, by incoming water pumped from a private water well).

Backflow preventers are indispensable to prevent contamination of the distribution network of the drinking water from entering from connected user units (for example, washing machines, boilers, industrial plants, hospitals, laboratories, fire fighting

plants). Backflow preventers BA type assure protection, in case of backflow, against the risk of pollution for types of water up to category 4, according reference standard EN1717. They are not suitable for water of category 5 (fluid presenting a human health hazard due to the presence of microbiological or viral elements);

in this case an air gap separation must be used

For correct installation, it is necessary to install a filter upstream with respect to the backflow preventer, in order to prevent problems caused by dirt and residual parts present in the piping, such as shut-off valves upstream and downstream with

respect to the backflow preventer.

Series ECO3F backflow preventer, even if marked PN10 complying with reference normative EN12729, due to its design and testing characteristics is suitable for installation in firefighting networks with service pressure of 12 bar.

Accessories

ECO3 TEST: control instrument

Special version

Pre-assembled unit

ECO3F Body: cast iron EN GJS 250

RAMPA Unit composed of: 2 shut-off valves + 1 Y strainer + 1 backfl ow preventer

Sizes: DN65÷150

Coating: RAL 5002 colour

PN Max 10 bar

Temp. -0 +65 °C

Drilling: PN10