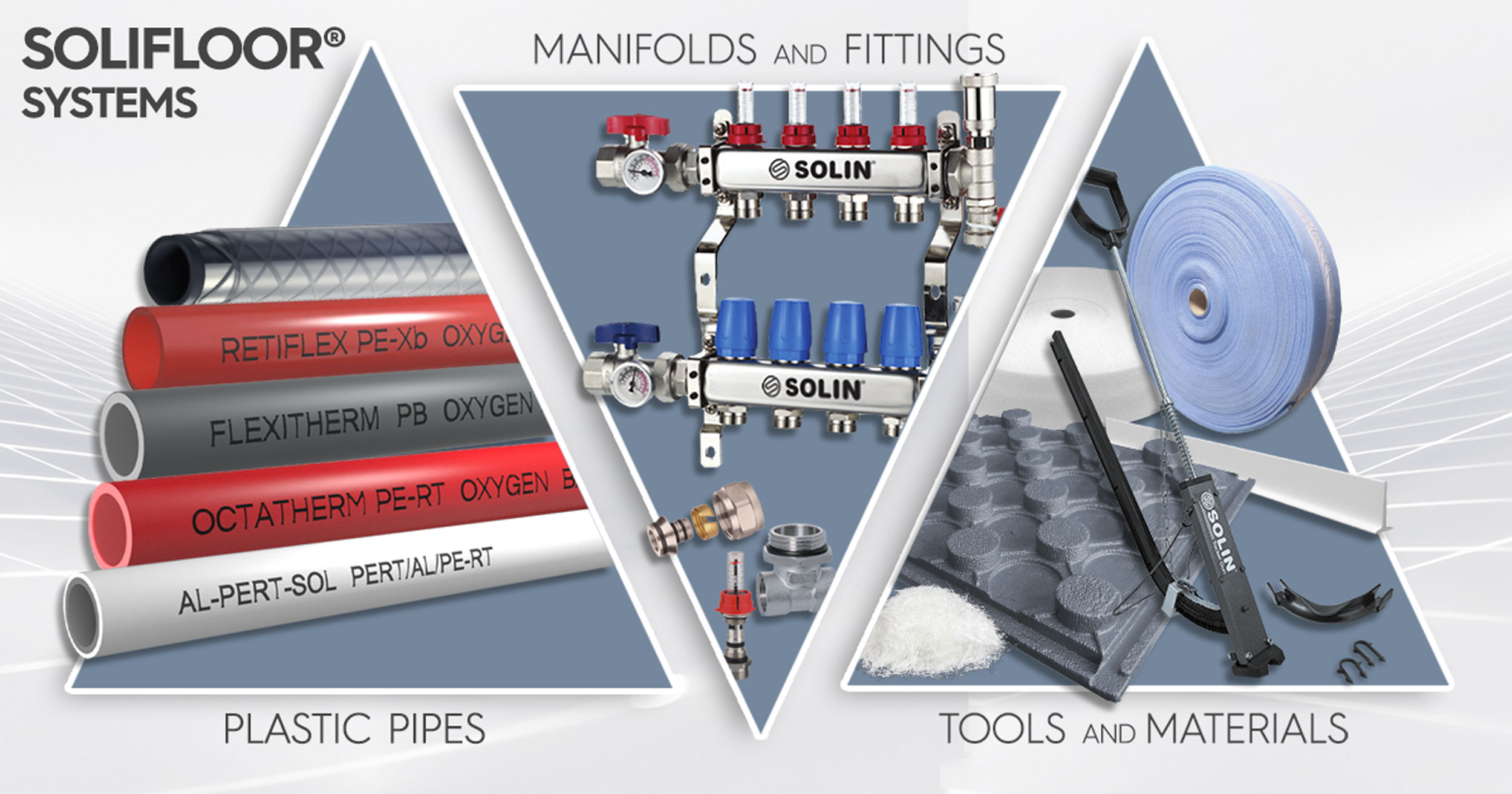

Description

Polyethylene pipes of increased temperatures resistance(PE-RT), with the commercial trade name OCTATHERM, are produced by special type of polyethylene DOWLEX 2344 E. Their unique molecular structure gives them high mechanical resistance to pressure and temperature combined with great flexibility and easy installation, without cross linking requirement.

They are particularly flexible with a smooth surface. They are produced according to DIN 16833/16834/4721/4726 specifications and are accompanied by quality certificates of German institutes, like SKZ for their mechanical resistance, MPA for oxygen barrier and by guarantee of 1.400.000EUR, that covers their good function. OCTATHERM pipes are in the market for more than 20 years and more specifically to installations of heating and sanitation with excellent results and their annual consumption is increasing year by year against other competitive pipes. They are produced in white or black color with UV stabilizers, with or without protective corrugated pipe. They are available in various coil lengths from 100m to 600m for single pipes and in 50m coils for pipes with protective corrugated pipe. They can be connected with many types of fittings, such as screw fittings, press fittings, speed fits, electro fusion etc.

Advantages

- Excellent thermal properties

- Great resistance to high temperatures in networks under pressure

- Resistance to corrosion and chemical substances.

- High mechanical resistance.

- Low friction rate

- Light, particularly flexible and economical

- Easy installation (particularly in under floor heating)

- Non toxic

- Certified by international institutes.

- Durability and longevity

- Weldable basic pipe

- Tight bending radius possible

- No incrustation due to smooth inner pipe surface

Specifications

- Density of raw material 0,933 gr/cm3, according to ASTM D1505

- Flow of raw material 0,64gr/10min, according to ASTM D1238 (190 OC/2,16 Kg)

- Thermal conductivity 0,4W/mK at 60OC, according to DIN 52612-1

- Linear elongation coefficient 1,95x10-4/K, according to DIN 53752 A at 20-70 °C.

- Softening limit (VICAT point) 123 °C, according to ASTM 1525

- Elasticity Factor 550 Mpa