Magnetite and dirt separators for heat pumps RBM MP1 and MP2

Description

Magnetite separators especially for heat pumps

Low pressure loss, high performance with a large flow range, a large collecting vessel, an extremely strong magnet as well as a fine-meshed filter network, ideally matched for hydraulic system conditions of heat pumps, but also wood heating systems: the new magnetite and sludge separators.

How it works

The MP1 and MP2 magnetite and sludge separators are equipped with a powerful neodymium magnet with 11,000 gauss as well as a fine-mesh filter insert. Due to this dual action, they reliably filter all magnetic and non-magnetic impurities from the heating system. The particularly large collection container makes both ideal for systems with heat pumps or wood heating systems.

How dual filtration works

Due to the change in cross-section of the filter chamber compared to the pipe, the heating water slows down there, the close-meshed filter insert catches all non-magnetic impurities exactly there. The magnetic impurities, such as magnetite, are then attracted and intercepted by the magnet mounted in the centre of the filter chamber. In this way, magnetic or ferrous and non-magnetic impurities are removed from the system and collected at the bottom of the large collection tank.

Maintenance

All necessary shut-off, draining and venting devices for maintenance are already integrated on both separators ex works. The drain ball valve is located at the bottom of the collection tank, the shut-off device and venting at the top of the filter housing. Without having to open the filter, the strong neodymium magnet can be pulled out downwards. Depending on how dirty the system is, this maintenance can also be carried out with cleaning of the filter screen. The unrivalled capacity of the collection tank accommodates longer maintenance intervals.

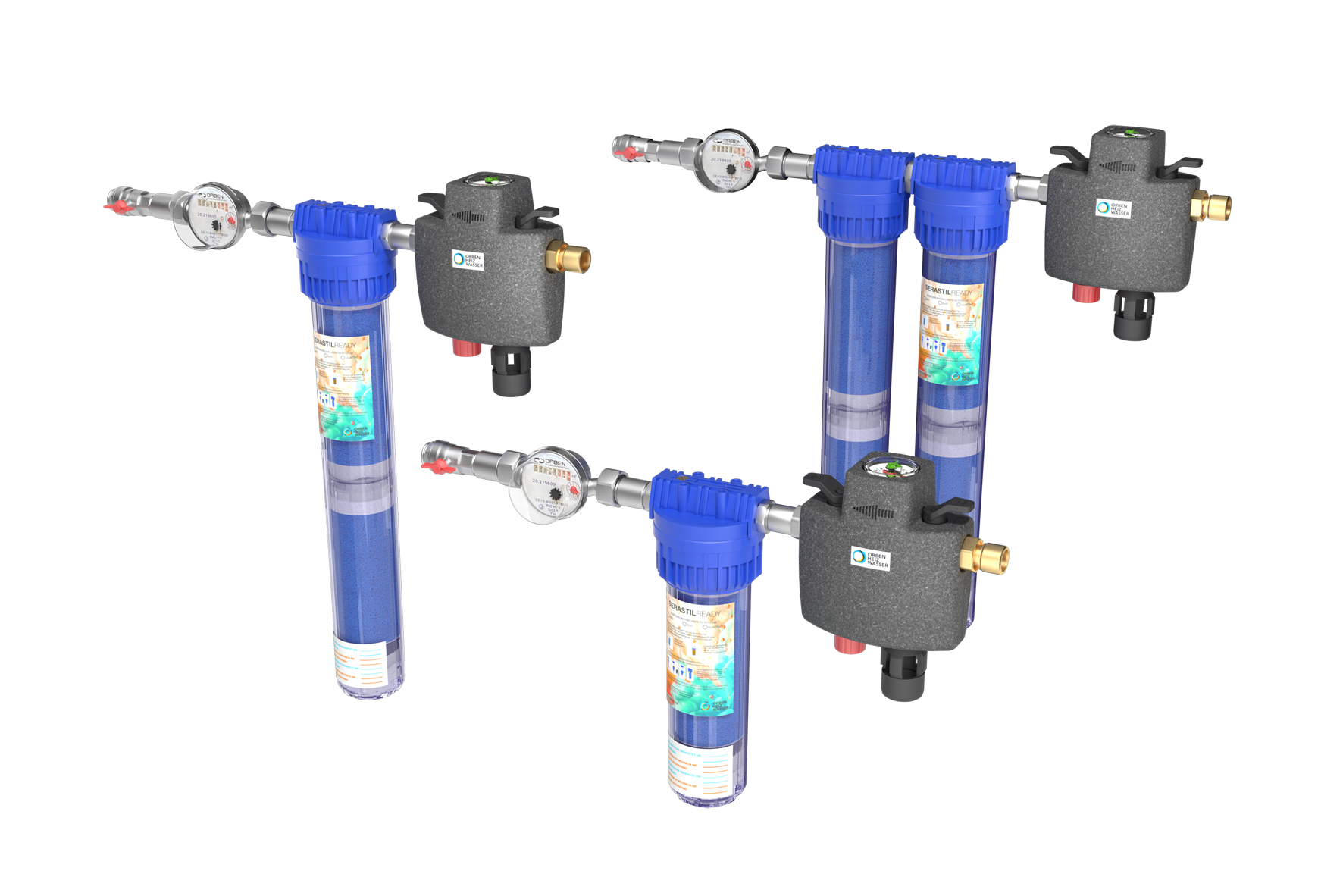

MP1 or MP2 - The difference is the installation situation

Magnetite and sludge separators should always be installed in the return before the heat generator to protect it from contamination, which usually comes from the system. However, not every system always offers enough space. The 28.5 cm high and 10 cm wide MP1 model stands out because of its large collection container. It should only be installed in horizontal pipelines. The more compact MP2 model is recommended for installation situations where there is not enough space. It can also be rotated 360° via the union nut of the diverter valve housing and installed horizontally, vertically or diagonally in almost all installation positions. Both models have a 1" connection and optional thermal insulation is available to maintain the heat level for reduced energy consumption, energy costs and CO2 emissions.

RBM and Orben

Since 2022, RBM and Orben Water Treatment have been going their separate ways in the D-A-CH region. Orben exclusively represents the range of magnetite, sludge and air separators in the three-stage distribution channel. The contact persons for the trade and wholesalers are Orben's experienced industrial and commercial representatives.

The family-owned company RBM from northern Italy with a turnover in the three-digit million range was founded in 1953 by the Bossini family near Brescia in northern Italy. The specialist has four of its own production facilities in the Brescia area near Lake Garda and six branches worldwide with more than 250 employees. RBM stands for an extremely high and automated vertical range of manufacture. The ultra-modern production facilities in nearby Italy guarantee a high level of delivery readiness, especially in times of strained global supply chains, and the ability to respond quickly and flexibly to new requirements and customer wishes thanks to in-house development and production. Especially in the field of magnetite and sludge separators, a large number of innovations have been successfully placed in other European countries in recent years.

Address

Orben Wasseraufbereitung GmbH & Co. KG

Rheingaustr. 190-196

65203 Wiesbaden

Germany

Telephone+49 611 9625722

Fax+49 611 9620964